Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Why Choose a Gear Reducer for Your Mechanical Needs?

In today’s fast-paced industrial environment, selecting the right components is crucial. Gear reducers play a vital role in mechanical applications. According to Dr. Richard Holt, a leading expert in motion control systems, “The efficiency gained from a well-chosen gear reducer can drastically improve machinery performance.”

Gear reducers are essential for various reasons. They enhance torque and reduce speed, which is beneficial for many machines. These devices help in optimizing energy usage. Without them, systems might struggle to function efficiently. The importance of gear reducers can often be underestimated, leading to less than optimal decisions.

However, picking the right gear reducer is not always straightforward. Factors such as size, load capacity, and efficiency must be carefully considered. Many industries face challenges due to improper selections. It's important to evaluate specific needs and expert opinions. Choosing wisely can prevent costly errors and enhance overall productivity. The insights from experts like Dr. Holt remind us of the long-term benefits of investing in quality gear reducers.

Understanding Gear Reducers: An Overview of Their Functionality

Gear reducers play a vital role in mechanical systems. They help in reducing the speed of motors while increasing torque. This leads to enhanced efficiency in various applications. According to a recent industry report, the global gear reducer market is projected to reach $11 billion by 2026. This indicates a growing reliance on these components across sectors.

Understanding how gear reducers function is crucial. They typically employ gears to decrease the input speed and provide a higher output torque. Different types of gear systems, like planetary and helical, achieve this in unique ways. A specific industry study reveals that planetary gear reducers can offer up to 95% efficiency. However, not all applications require such high efficiency, leading to potential over-engineering.

The design choices in gear reducers also invite scrutiny. Some systems may use heavier materials for durability, but this can increase the overall weight. In high-performance sectors, this might be an issue. It is also essential to consider maintenance needs. A lack of proper upkeep can lead to inefficiencies and increased wear. Understanding these nuances helps in making informed decisions.

Key Advantages of Using Gear Reducers in Mechanical Systems

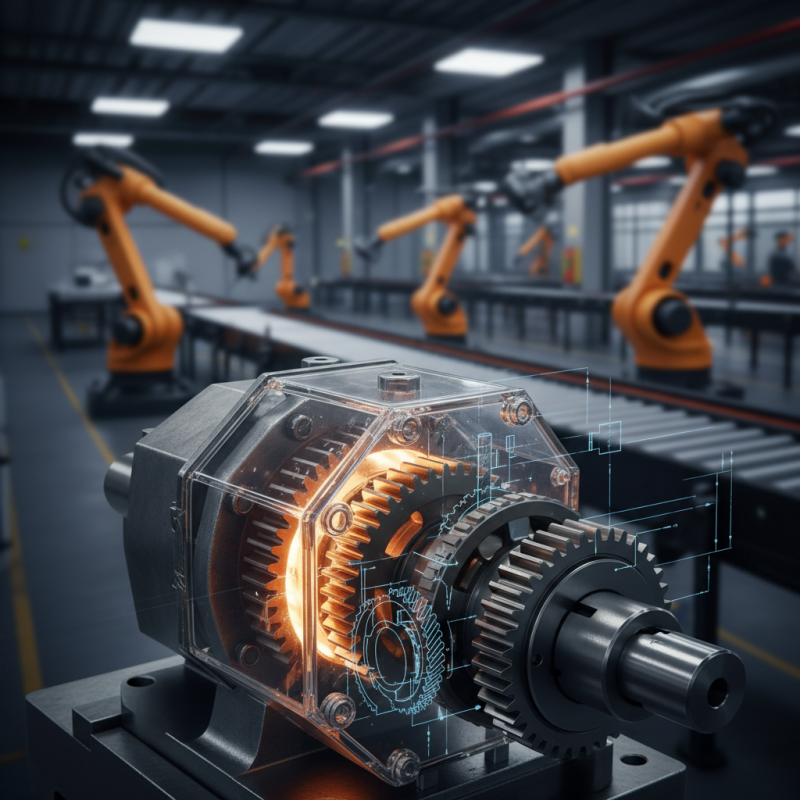

Choosing a gear reducer can significantly enhance mechanical systems. These devices are known for their efficiency in reducing speed and increasing torque. By transforming the motor's power into usable energy, gear reducers ensure smoother operations. Their compact design allows for easy integration into various applications, from robotics to automotive industries.

One key advantage is the efficiency boost. Gear reducers minimize energy loss during speed reduction. They convert high-speed, low-torque inputs into high-torque outputs. This function is crucial in preventing motor overload and ensuring durability. Additionally, they help maintain consistent speeds, even under heavy loads.

While the benefits are clear, some challenges exist. Incorrect sizing can lead to inefficiencies. Oversized reducers may complicate installations. On the other hand, undersized ones can cause premature failures. Therefore, thorough analysis is essential before selection. Understanding specific mechanical needs helps avoid costly mistakes and maximizes performance.

Common Applications of Gear Reducers Across Various Industries

Gear reducers are vital components in many industries. They adjust speed and torque, making machinery operate more efficiently. In manufacturing, for example, gear reducers help conveyor belts transport materials. Their role in automating processes cannot be overlooked. They enable precision, which is crucial for consistent output.

In the automotive sector, gear reducers are used in electric vehicles. They increase torque, helping achieve better acceleration and efficiency. Similarly, in construction, gear reducers operate heavy machinery. Equipment like cranes and excavators rely on them to lift heavy loads. Without effective gear reduction, these machines would struggle to perform.

Precision matters, yet not all designs work perfectly. Some applications may experience overheating or wear faster than expected. This indicates a need for regular maintenance and improvements in design. Choosing the right gear reducer is essential. A mismatch can lead to inefficiencies and costly downtime.

Factors to Consider When Selecting a Gear Reducer for Your Needs

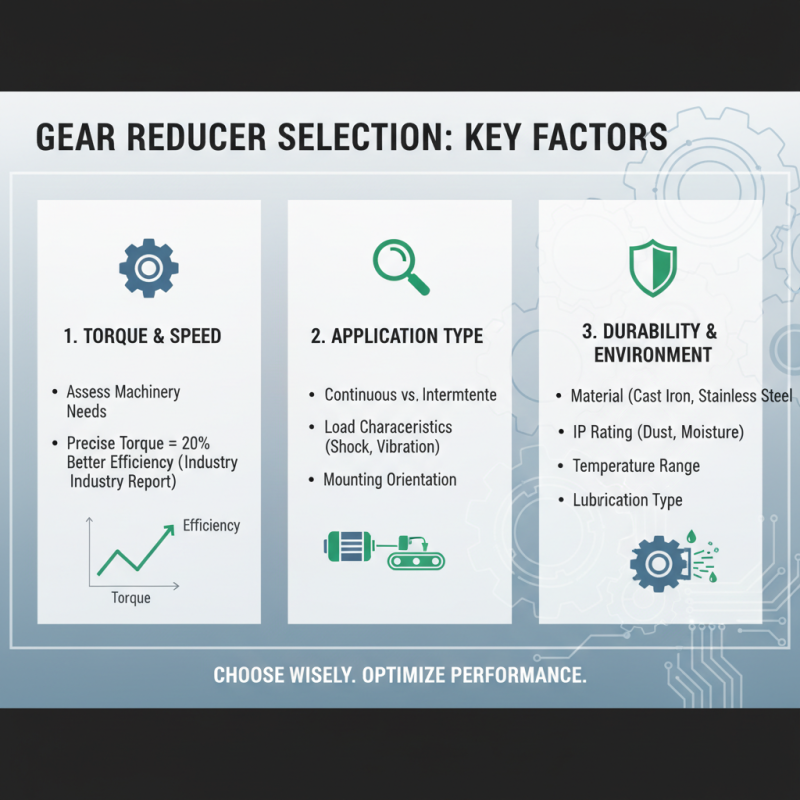

Choosing the right gear reducer can be crucial for your mechanical applications. Various factors play a vital role in this decision-making process. For instance, the torque and speed requirements of your machinery should be carefully assessed. According to industry reports, precise torque ratings can improve transmission efficiency by up to 20%. Yet, many overlook this aspect, leading to potential inefficiencies.

Another essential consideration is the gear ratio. The right gear ratio directly impacts performance. A mismatch can result in excessive wear and tear, compromising durability. In fact, studies show that incorrect gear ratios can shorten equipment lifespan by more than 30%. This highlights the need for thorough evaluations.

Space constraints also deserve attention. Many designs require compact solutions. However, opting for a smaller gear reducer without proper analysis may lead to overheating issues. This can hinder the unit’s longevity. It’s crucial to balance size and performance. While it can be tempting to choose smaller models, the long-term consequences might outweigh initial benefits.

Maintenance Tips for Ensuring Longevity of Gear Reducers

Regular maintenance of gear reducers is vital for optimal performance. Lubrication plays a key role here. Use the right type of oil. Change it regularly. Over time, old oil can cause friction. Friction leads to wear. Keep a schedule for oil changes. An unexpected breakdown is costly.

Another tip is monitoring the temperature. Excess heat can be damaging. Install a temperature gauge if possible. If it exceeds recommended levels, inspect the system. This is especially crucial during heavy usage. If you notice unusual noises, do not ignore them. They often signal underlying problems.

Vibration analysis is also essential. Regular checks can identify issues early. A simple imbalance can affect the entire system. It’s important to address these concerns promptly. Neglecting these maintenance tips may lead to significant failures. Reflecting on past maintenance routines is a good practice. Were you thorough enough? Continuous improvement in maintenance helps ensure longevity.

Gear Reducer Efficiency and Maintenance Insights

Related Posts

-

Top Strategies for Implementing EMI Filters in VFD Applications for Enhanced Performance

-

Top 10 Benefits of Using VFD Controllers in Industrial Applications

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

What is a Single Phase VFD and How Does it Work?

-

Challenges When Choosing the Best Emi Filter for Vfd Applications

-

Understanding the Benefits of Variable Speed Drives in Modern Industry