Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Unlocking Energy Efficiency: How Motor Frequency Converters Transform Industrial Operations

In today's competitive industrial landscape, optimizing energy efficiency is paramount for sustainability and cost-effectiveness. The integration of motor frequency converters has emerged as a pivotal solution, revolutionizing operations across various sectors. According to a 2022 report by the International Energy Agency, industrial motors account for nearly 70% of global energy consumption in the sector, highlighting the critical need for innovations that enhance efficiency.

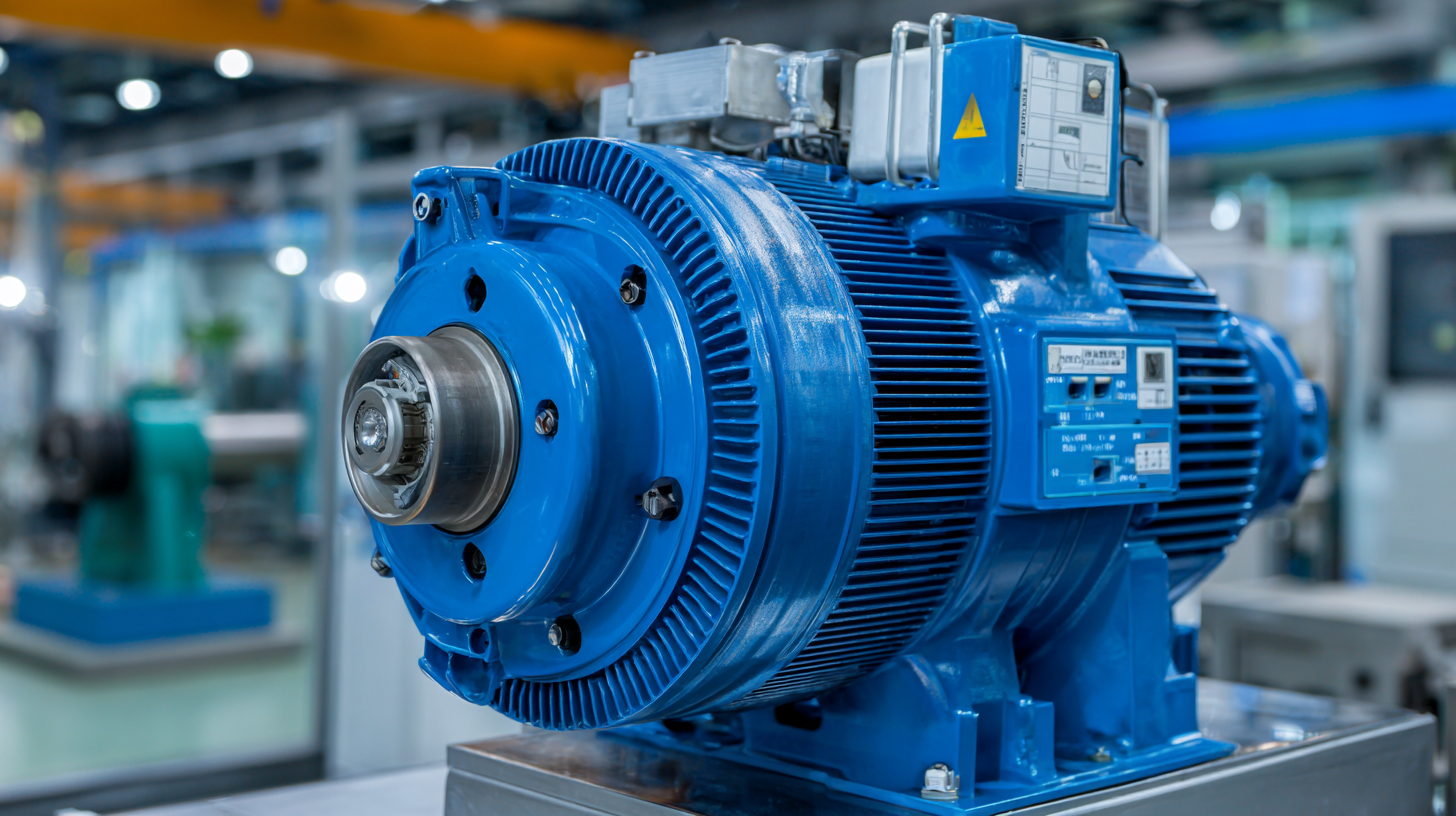

Motor frequency converters, also known as variable frequency drives (VFDs), enable precise control over motor speeds, resulting in energy savings of up to 50% in some applications. This transformative technology not only reduces energy costs but also extends equipment lifespan and minimizes maintenance requirements. As industries increasingly prioritize green initiatives and operational excellence, understanding the capabilities and benefits of motor frequency converters will be essential for future advancements in industrial efficiency.

The Role of Motor Frequency Converters in Enhancing Energy Efficiency in Industries

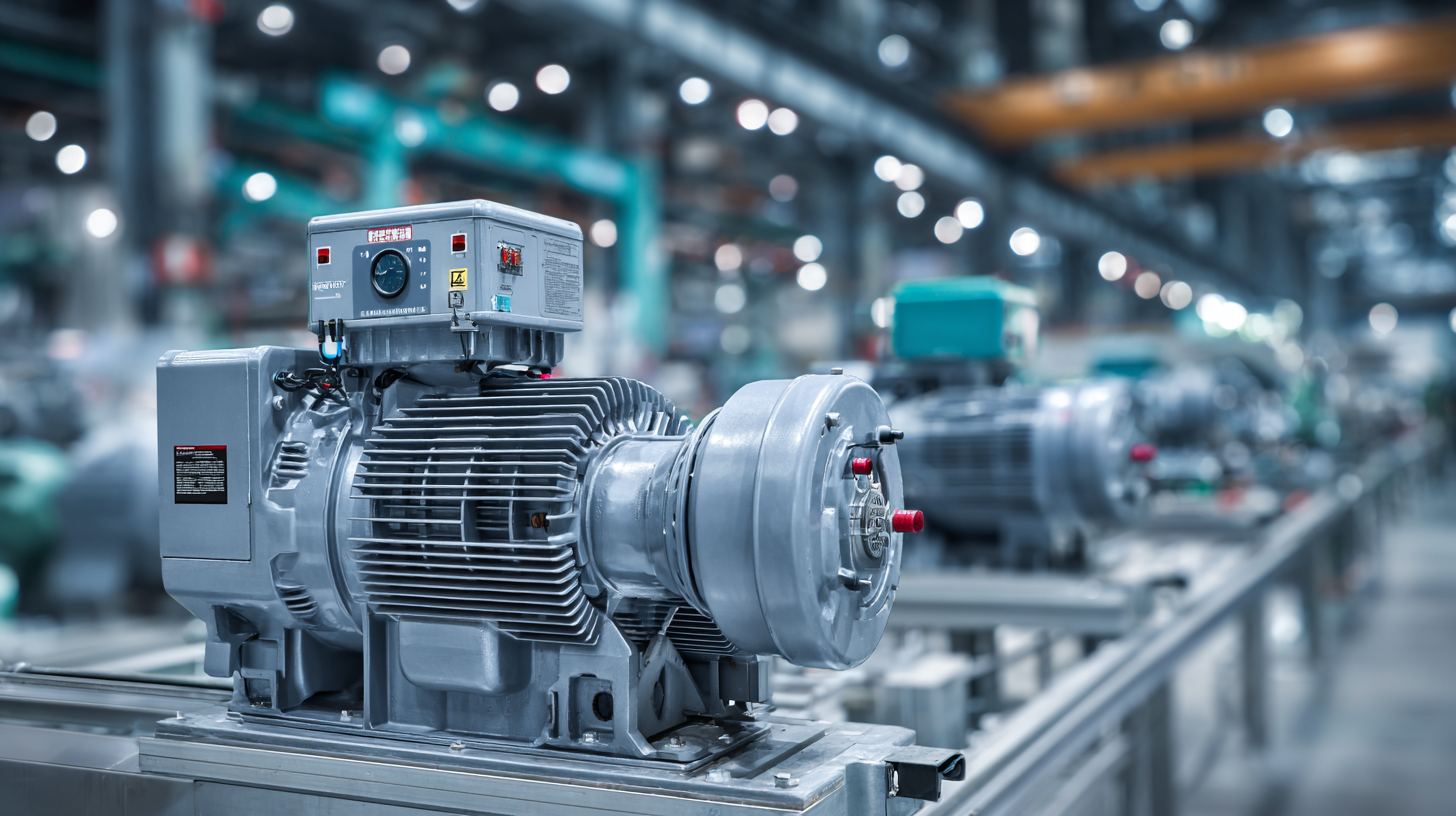

Motor frequency converters play a pivotal role in enhancing energy efficiency across various industrial operations. By adjusting the speed and torque of electric motors, these devices ensure that machinery operates only at the required levels, significantly reducing energy consumption. This capability not only leads to substantial cost savings but also minimizes wear and tear on equipment, extending its service life. As industries strive to meet sustainability goals, the adoption of motor frequency converters has become a strategic imperative.

**Tips**: To maximize the benefits of motor frequency converters, ensure proper sizing and selection based on your specific application needs. Regular maintenance checks are crucial to keep the system running optimally and can prevent potential inefficiencies caused by wear or environmental factors. Additionally, consider training staff on best practices for operating and troubleshooting these systems to further enhance energy efficiency.

In an era where energy efficiency is key to operational excellence, integrating motor frequency converters is a smart move for industries looking to boost performance while reducing their carbon footprint. By embracing this technology, companies can align their operations with modern efficiency standards, fostering both economic and environmental sustainability.

Statistical Insights: Energy Savings Achieved Through Frequency Conversion Technologies

Frequency conversion technologies, particularly motor frequency converters, have emerged as a game-changing solution for enhancing energy efficiency in industrial operations. By allowing motors to run at varied speeds, these converters enable precise control over energy consumption, leading to significant cost savings. For instance, industries that have implemented frequency converters report energy savings of up to 30% compared to traditional systems. This reduction not only lowers operational costs but also contributes to a more sustainable industrial ecosystem.

Statistical analyses further underscore the effectiveness of frequency conversion technologies. Surveys indicate that companies utilizing these systems have experienced a marked decrease in energy waste and improved overall productivity. Additionally, with the rising cost of energy, the adoption of motor frequency converters has become a strategic move for organizations aiming to optimize their resource usage while maintaining output efficiency. This transition towards frequency conversion not only benefits the bottom line but also aligns with global energy conservation goals, demonstrating the profound impact these technologies can have on industrial operations.

Case Studies: Success Stories of Industrial Operations Transforming with Frequency Converters

In the industrial sector, the integration of motor frequency converters has proven pivotal in driving energy efficiency and operational excellence. Case studies highlight the transformative impact these converters have on various industries. For instance, a study by the U.S. Department of Energy found that upgrading to variable frequency drives (VFDs) can result in energy savings of 20-50% for motors in industrial settings. A prominent example involves a major automotive manufacturer that implemented VFDs across their assembly lines, reducing their energy consumption by 30% and translating to annual savings of over $250,000.

Another compelling case is seen in the water treatment industry, where frequency converters have also optimized pump operations. A recent report by the International Energy Agency revealed that the adoption of VFDs in pumping systems can achieve energy savings of up to 30%, while simultaneously enhancing system reliability and reducing maintenance costs. One water utility company documented a significant reduction in energy costs, estimating a savings of around $100,000 annually after retrofitting their pumps with frequency converters. These real-world examples demonstrate the profound effect of motor frequency converters in reshaping not only energy consumption but also operational performance across various industrial domains.

Comparative Analysis: Energy Consumption Before and After Implementing Frequency Converters

The comparative analysis of energy consumption before and after implementing motor frequency converters highlights their transformative impact on industrial operations. Studies show that motor frequency converters can reduce energy consumption by up to 30% compared to traditional motor systems. This significant decline in energy use is particularly beneficial in scenarios where variable loads are present, enabling companies to achieve not only cost savings but also substantial reductions in their carbon footprints.

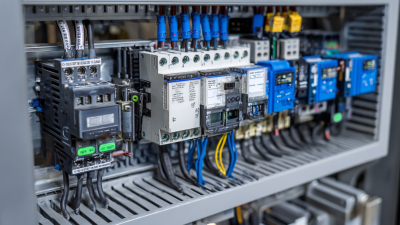

Furthermore, the integration of advanced energy management systems alongside variable frequency drives amplifies these benefits. For instance, the efficient management of energy consumption in industrial setups has been demonstrated to enhance overall operational efficiency. Reports indicate that utilizing these systems can lead to lower total harmonic distortion (THD) levels, thereby improving power quality and equipment lifespan. In sectors such as manufacturing and renewable energy integration, the adoption of motor frequency converters plays a vital role in optimizing performance and ensuring sustainable operations.

Unlocking Energy Efficiency: How Motor Frequency Converters Transform Industrial Operations

| Operation Type | Energy Consumption (Before, kWh) | Energy Consumption (After, kWh) | % Reduction | Cost Savings (Annually, $) |

|---|---|---|---|---|

| Pumping Systems | 150,000 | 100,000 | 33% | $25,000 |

| Conveyor Systems | 200,000 | 140,000 | 30% | $18,000 |

| HVAC Systems | 250,000 | 180,000 | 28% | $40,000 |

| Compressors | 300,000 | 210,000 | 30% | $55,000 |

| Fans and Blowers | 180,000 | 120,000 | 33% | $22,000 |

Future Trends: Innovations in Motor Frequency Converters and Their Impact on Industrial Energy Management

The advent of motor frequency converters has significantly altered the landscape of industrial energy management. According to a report from the U.S. Department of Energy, implementing variable frequency drives (VFDs) can improve energy efficiency by up to 25-50% in certain applications. These devices allow for precise control of motor speed and torque by adjusting the frequency and voltage of the power supplied, enabling industries to optimize their processes while reducing energy consumption. As sustainability becomes a priority, innovations in motor frequency converters are set to play a crucial role in meeting energy efficiency targets.

Looking ahead, the future of motor frequency converters is driven by technological advancements such as IoT integration and machine learning. A study by Grand View Research indicates that the global market for variable frequency drives is expected to reach $22.34 billion by 2025, with a CAGR of 6.4%. This growth is largely attributed to increased awareness of energy conservation and the implementation of smarter industrial solutions. Enhancements in digital control technologies and predictive maintenance are enabling facilities to harness real-time data, leading to more informed decisions and further improving operational efficiency. With these trends, motor frequency converters are set to become indispensable tools for industries seeking to elevate their energy management strategies.

Related Posts

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

5 Reasons Why Frequency Drive Controllers Are Essential for Global Procurement Success

-

Unlocking Efficiency in Industrial Applications How to Use the Best Single Phase to 3 Phase Converter VFD

-

5 Essential Reasons to Choose EMI Filters for Your Electronic Devices

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive