Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

2025 Top Innovations in Single Phase Motor Inverter Technology for Energy Efficiency

In recent years, the demand for enhanced energy efficiency has driven substantial innovations in various sectors, particularly in motor control technologies. According to the International Energy Agency (IEA), motors account for approximately 70% of global industrial electricity consumption, highlighting the critical need for advancements that not only optimize performance but also reduce energy waste. Among these technological advancements, single phase motor inverters have emerged as a focal point of innovation due to their versatility and efficiency in residential and light commercial applications.

With the shift towards sustainable energy solutions, the market for single phase motor inverters is projected to grow significantly. A recent report by MarketsandMarkets anticipates that innovations in inverter technology will contribute to an annual growth rate of 8.5% in the segment by 2025. This growth is largely attributed to improvements in inverter design, such as the implementation of advanced control algorithms and integration with renewable energy sources. As stakeholders seek to harness the full potential of single phase motor inverters, these innovations promise not only enhanced energy efficiency but also the ability to meet the evolving demands of a greener future.

Future Trends in Single Phase Motor Inverter Design for Enhanced Energy Efficiency

The future trends in single-phase motor inverter design are pivotal for enhancing energy efficiency across various industries. According to the International Energy Agency, electric motors account for nearly 45% of global electricity consumption, emphasizing the need for improved inverter technologies to minimize energy waste. The latest innovations focus on the integration of advanced control algorithms, which optimize motor performance by adjusting operational parameters in real-time, thus providing significant energy savings. For instance, the adoption of vector control methods in single-phase motor inverters has shown to improve efficiency by up to 30% compared to traditional techniques.

Moreover, the development of smart inverters that utilize IoT technology is revolutionizing energy management. These inverters not only improve the operational efficiency of single-phase motors but also enable predictive maintenance, reducing downtime and extending equipment lifespan. A recent report by MarketsandMarkets anticipates the global market for intelligent motor control systems to grow from $8 billion in 2020 to over $12 billion by 2025, reflecting a strong trend towards automation and energy efficiency in motor systems. As the adoption of renewable energy sources increases, the role of sophisticated single-phase motor inverters in optimizing energy usage becomes even more critical.

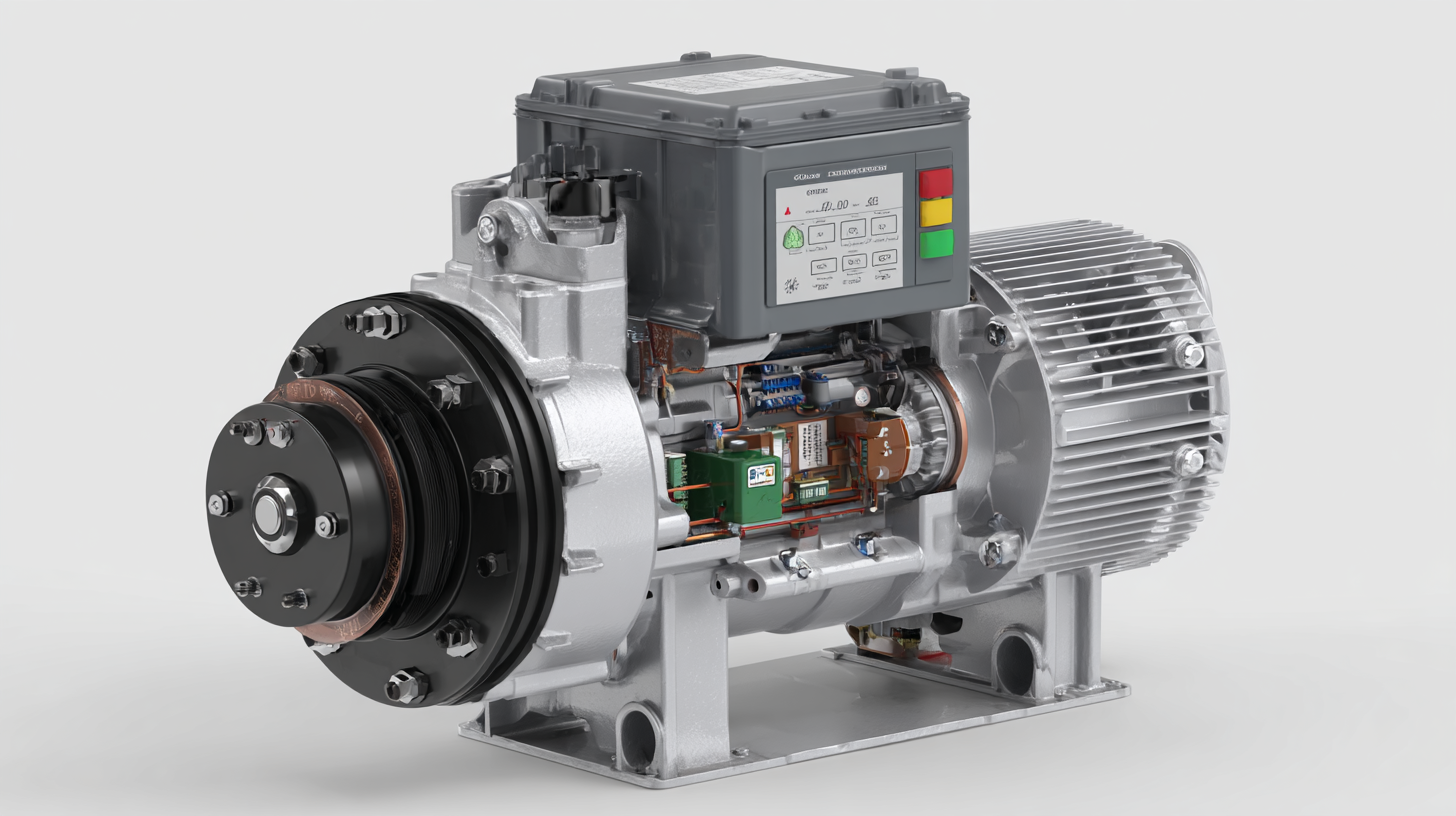

Innovative Materials and Components Revolutionizing Inverter Performance

The advancements in innovative materials and components are significantly transforming the performance of single phase motor inverters, particularly in the realm of energy efficiency. Recent reports indicate that the implementation of wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), can improve inverter efficiency by up to 30% compared to traditional silicon-based technologies. These materials not only enhance thermal conductivity but also permit higher operation frequencies, resulting in a compact design and reduced overall system weight.

Furthermore, advancements in passive components, such as inductors and capacitors, contribute to improved electromagnetic compatibility and minimized losses. For instance, the introduction of high-density ceramic capacitors can yield a 20% reduction in size while maintaining or enhancing performance. This optimization leads to longer-lasting components and lower maintenance costs, providing an attractive value proposition for manufacturers and users alike.

Tips: When selecting an inverter for applications requiring high reliability, consider those utilizing innovative materials like SiC and GaN, as they offer not only superior performance but also greater durability. Additionally, always evaluate the total cost of ownership, factoring in energy savings and maintenance needs, as high-efficiency solutions can lead to significant long-term savings.

2025 Top Innovations in Single Phase Motor Inverter Technology for Energy Efficiency

This chart represents the estimated energy efficiency improvements in single-phase motor inverter technology for 2025, highlighting the key innovations driving these advancements.

Integrating Smart Technologies in Single Phase Motor Inverters for Efficiency

The integration of smart technologies in single phase motor inverters marks a significant leap towards enhanced energy efficiency. By leveraging advanced algorithms and real-time data analytics, these innovative systems can optimize motor performance based on varying load conditions. Smart inverters are equipped with capabilities to monitor energy consumption, offering insights into usage patterns and enabling predictive maintenance. This not only reduces downtime but also maximizes operational efficiency, making them invaluable in a variety of industrial and residential applications.

The integration of smart technologies in single phase motor inverters marks a significant leap towards enhanced energy efficiency. By leveraging advanced algorithms and real-time data analytics, these innovative systems can optimize motor performance based on varying load conditions. Smart inverters are equipped with capabilities to monitor energy consumption, offering insights into usage patterns and enabling predictive maintenance. This not only reduces downtime but also maximizes operational efficiency, making them invaluable in a variety of industrial and residential applications.

Furthermore, the incorporation of Internet of Things (IoT) connectivity in single phase motor inverters allows for seamless integration into smart grid systems. This connectivity facilitates remote monitoring and control, empowering users to manage their energy consumption proactively. With feedback mechanisms in place, users can adjust settings based on real-time electricity rates or environmental conditions, driving further energy savings. As these technologies continue to evolve, they promise to transform single phase motor systems into intelligent units that not only conserve energy but also contribute to a more sustainable future.

Real-World Applications of Next-Gen Inverters in Energy-Intensive Industries

The evolution of single-phase motor inverter technology is poised to significantly enhance energy efficiency across energy-intensive industries. With advancements like the new generation of inverters, which promise high power density and improved performance, businesses can expect substantial cost savings and reduced carbon footprints. For instance, recent reports project that the global silicon carbide market will witness robust growth, highlighting how materials like silicon carbide are transforming inverter capabilities and facilitating the deployment of high-performance systems in various sectors.

Real-world applications of next-gen inverters are already making waves in industries such as manufacturing and HVAC. For example, companies are beginning to adopt advanced metering infrastructure (AMI 2.0), which not only enhances grid resiliency but also promotes decarbonization efforts by enabling more efficient energy use. This drive towards intelligent energy solutions is complemented by innovations in autonomous energy grids, ensuring that industries can effectively manage and optimize energy consumption as technologies evolve. As these trends gain momentum, industries are urged to embrace modern inverter technologies to stay competitive and achieve sustainability goals.

Comparative Analysis of Leading Single Phase Motor Inverter Technologies in 2025

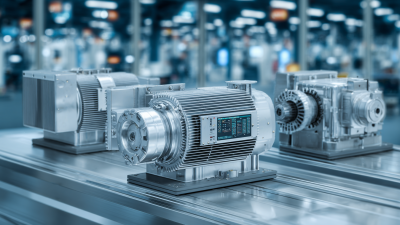

In 2025, the landscape of single phase motor inverter technology is undergoing significant transformation, focused on enhancing energy efficiency. Key players in the market are leveraging advanced materials and smart algorithms to optimize performance. One standout innovation is the integration of AI-driven controls, which enable real-time adjustments based on load conditions, ensuring that energy consumption is minimized without compromising on output.

Tips for consumers looking to optimize their use of single phase motor inverters include selecting models with energy-saving features and monitoring their efficiency ratings. It's essential to understand that investing in high-quality inverters not only enhances operational efficiency but also reduces long-term energy costs. Moreover, keeping up-to-date with the latest technological advancements can help end-users make informed decisions that align with sustainability goals.

Another trend observed in 2025 is the move towards modular inverter designs. These allow for easier upgrades and maintenance, further enhancing their longevity and efficiency. For those interested in these technologies, it's advisable to consult with industry experts and consider local regulations, as advancements often come hand-in-hand with evolving standards. Adopting these innovative solutions can significantly contribute to a greener environment and lower operational costs.

2025 Top Innovations in Single Phase Motor Inverter Technology for Energy Efficiency

| Technology | Efficiency (%) | Power Factor | Cost ($) | Cooling Type | Modulation Technique |

|---|---|---|---|---|---|

| Variable Frequency Drive (VFD) | 95 | 0.98 | 500 | Air Cooling | Pulse Width Modulation (PWM) |

| Direct Torque Control (DTC) | 97 | 0.95 | 750 | Liquid Cooling | Space Vector Modulation (SVM) |

| Sensorless Vector Control (SVC) | 93 | 0.97 | 600 | Air Cooling | Open Loop Control |

| Fuzzy Logic Control | 92 | 0.94 | 650 | Hybrid Cooling | Adaptive Modulation |

Related Posts

-

The Future of Efficiency: Exploring the Benefits of Single Phase Motor Inverters in Modern Applications

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

-

Exploring the Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings in Modern Applications

-

10 Best VFD Controllers You Need to Know for Optimal Performance

-

Exploring VFD Drives Industry Trends at the 2025 China 138th Canton Fair

-

How to Select the Right Motor Inverter for Your Industrial Application