Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Understanding Single Phase VFD: Benefits, Applications, and Buying Guide

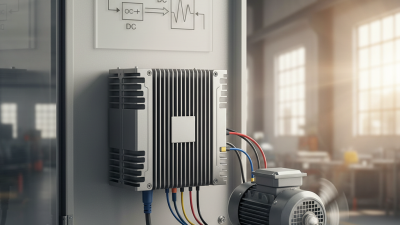

In today's rapidly evolving technological landscape, the demand for efficient and versatile motor control solutions has never been greater. Among these solutions, the single phase VFD (Variable Frequency Drive) stands out as a practical choice for various applications, especially in residential and light commercial settings. Understanding the inner workings and benefits of a single phase VFD can empower users to optimize their operations, enhance energy efficiency, and prolong the lifespan of their equipment.

The primary advantage of utilizing a single phase VFD lies in its ability to smoothly control the speed and torque of single-phase motors, which are commonly used in a range of devices such as fans, pumps, and conveyors. This capability not only helps in achieving precise motion control but also contributes to significant energy savings by allowing motors to operate only at the required speeds, reducing wasted energy. Moreover, a single phase VFD can provide protection against common electrical issues, ultimately enhancing system reliability.

As we delve deeper into the various aspects of single phase VFDs, including their applications, significant benefits, and key factors to consider when purchasing one, readers will gain a comprehensive understanding of how these devices can transform their operational efficiency and support sustainable practices. Whether you're a seasoned engineer or a novice seeking effective solutions for your motor systems, this guide aims to equip you with the necessary knowledge to harness the full potential of single phase VFD technology.

Understanding Single Phase VFD: Definition and Key Features

Single Phase Variable Frequency Drives (VFDs) are crucial components in modern motor control applications, enabling precise speed regulation, enhanced efficiency, and energy savings. At their core, single-phase VFDs convert fixed-frequency AC power into a variable frequency output, allowing for adjustable motor speed based on application requirements. This is particularly beneficial for home appliances, HVAC systems, and small industrial machines, where simple speed control is necessary. According to industry reports, the global VFD market is projected to grow at a CAGR of 7.4% between 2023 and 2028, indicating a rising demand for such versatile solutions.

Key features of single-phase VFDs include overload protection, integrated fault diagnostics, and user-friendly interface designs. These drives often come equipped with advanced modulation techniques to improve motor performance and reduce harmonic distortion. Notably, a research study published in the Journal of Electrical Engineering highlights that employing VFDs can lead to energy savings of up to 30% in typical motor applications. Furthermore, their compact design and easy integration into existing systems make them an attractive choice for businesses looking to optimize operations without significant infrastructure changes.

Key Benefits of Using Single Phase VFD in Various Applications

Single phase variable frequency drives (VFDs) offer significant advantages across various applications, particularly in residential and light commercial settings. One of the key benefits of using single phase VFDs is their enhanced energy efficiency. By adjusting the frequency and voltage of the power supplied to motors, these drives optimize performance and reduce power consumption. This can lead to substantial energy savings over time, making them an attractive choice for users seeking to lower utility bills while minimizing their environmental footprint.

Another notable advantage is the flexibility and control that single phase VFDs provide. They allow users to fine-tune the speed and torque of their motors to match specific operational needs. This level of adjustment not only improves the performance of equipment, such as pumps and fans but also extends the lifespan of the machinery by reducing wear and tear. Additionally, single phase VFDs can simplify the integration of automation and smart technologies, enabling smoother operations and real-time performance monitoring, which is crucial in a variety of applications, from HVAC systems to agricultural equipment.

Key Benefits of Using Single Phase VFD in Various Applications

Common Applications of Single Phase VFD in Industries and Homes

Single phase variable frequency drives (VFDs) have gained popularity across various industries and residential applications due to their efficiency and versatility. In industrial settings, single phase VFDs are commonly employed to control the speed of electric motors in machinery such as conveyors, fans, and pumps. These drives facilitate precise control over motor performance, enabling enhanced productivity and energy savings. By adjusting the frequency and voltage supplied to the motor, businesses can tailor operational speeds to match specific requirements, reducing wear and tear while optimizing processes.

In residential applications, single phase VFDs are used in HVAC systems, swimming pool pumps, and various household appliances that require motor control. For example, homeowners can benefit from using VFDs in air conditioning units, which allows for variable speeds of compressors, enhancing comfort and reducing energy consumption. Additionally, swimming pool pumps equipped with single phase VFDs can operate at different speeds based on filtering and circulation needs, significantly cutting down on electricity bills while maintaining clean and safe pool water. The growing adoption of single phase VFDs highlights their importance in improving energy efficiency, reducing operational costs, and offering greater control in both industrial and home environments.

Factors to Consider When Buying a Single Phase VFD

When considering the purchase of a single phase Variable Frequency Drive (VFD), several key factors should be thoroughly evaluated to ensure optimal performance and alignment with application requirements. First and foremost, the power rating of the VFD must match the motor specifications. According to industry standards, it is advisable to select a VFD that can handle at least 120% of the motor's current capacity to account for potential overloads and to enhance the system's durability. Analyzing the voltage compatibility is equally crucial, as mismatches can lead to significant performance issues and damage to the equipment.

Another vital aspect to consider is the control method employed by the VFD. Single phase VFDs can operate using various techniques, including scalar control and vector control. A report by the International Energy Agency (IEA) notes that vector control systems, while typically more expensive, offer enhanced efficiency and better torque performance, making them suitable for applications requiring precision in speed and torque adjustments. Additionally, it’s essential to evaluate the environmental conditions where the VFD will be installed, as options with specific ingress protection (IP) ratings may be necessary to guard against dust, moisture, or temperatures that fall outside typical operational ranges.

Maintenance Tips for Longevity of Single Phase VFD Units

Maintaining the longevity of single phase Variable Frequency Drives (VFDs) is essential for maximizing their efficiency and performance in various applications. Regular maintenance routines can significantly extend the lifespan of these units and ensure they operate smoothly. One critical aspect of maintenance is ensuring proper cooling and ventilation. Overheating is a common issue that can lead to premature failure. Therefore, keeping the VFD’s cooling vents unobstructed and cleaning any dust or debris build-up regularly helps maintain optimal operating conditions.

Another important maintenance tip is to routinely inspect and tighten all electrical connections. Loose wires can result in excessive heat generation, leading to component damage and system inefficiencies. Additionally, checking for any signs of wear or damage to the unit’s components, such as capacitors and circuit boards, can help identify potential issues before they escalate into costly repairs. Implementing a scheduled maintenance plan that includes these inspections and cleaning tasks will ensure your single phase VFD operates reliably while reducing downtime and repair costs.

Related Posts

-

What is a Single Phase VFD and How Does it Work for Your Applications

-

Unlocking Energy Efficiency: How Motor Frequency Converters Transform Industrial Operations

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

How to Select the Right Motor Inverter for Your Industrial Application

-

Exploring VFD Drives Industry Trends at the 2025 China 138th Canton Fair

-

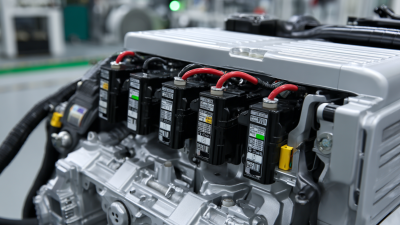

Why Motor Inverters Are Essential for Modern Electric Vehicles