Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

What is a Single Phase VFD and How Does it Work for Your Applications

In today's rapidly evolving industrial landscape, the demand for efficient and reliable motor control solutions has never been more critical. A Single Phase VFD (Variable Frequency Drive) serves as a vital component in this context, allowing for enhanced performance in various applications. According to a recent market report by Research and Markets, the global market for variable frequency drives is projected to grow significantly, driven by the increasing need for energy-efficient solutions in sectors such as manufacturing, HVAC, and water treatment. Specifically, single phase VFDs play a crucial role in residential and small industrial applications, where they optimize motor speed and torque, leading to improved operational efficiency.

The functionality of a single phase VFD is rooted in its ability to modulate power frequency and voltage, adjusting motor performance directly to meet specific load requirements. This adaptability not only minimizes energy consumption—often cited to be as much as 60% in energy savings— but also prolongs the lifespan of the associated machinery. As industries continue to pursue sustainability and cost-effectiveness, the integration of single phase VFDs is becoming increasingly prominent, with estimates suggesting that more than 70% of industrial motors could benefit from the implementation of variable frequency drives in the near future. This article delves into the workings of single phase VFDs and their potential applications, uncovering the transformative impact they can have on operational efficiencies.

Understanding Single Phase VFDs: Key Features and Benefits

A single-phase variable frequency drive (VFD) is an innovative solution for controlling the speed and torque of electric motors in various applications. One of the key features of single-phase VFDs is their ability to modulate the frequency and voltage supplied to a motor, enabling more precise control over its performance. This capability is particularly beneficial in residential and light commercial settings where three-phase power is not readily available. By utilizing a single-phase VFD, users can optimize energy consumption and extend the lifespan of their motors.

The benefits of implementing a single-phase VFD are substantial. Not only do they enhance energy efficiency, but they also allow for smoother operation and reduced wear on mechanical components. This results in lower maintenance costs and fewer system failures. Additionally, single-phase VFDs offer features such as adjustable ramp-up and ramp-down times, overload protection, and integrated diagnostics, which provide users with a comprehensive tool for managing motor-driven applications. Overall, the use of these drives in everyday settings empowers users to achieve significant operational improvements while maintaining ease of use and installation.

How Single Phase VFDs Operate: An In-Depth Look at the Technology

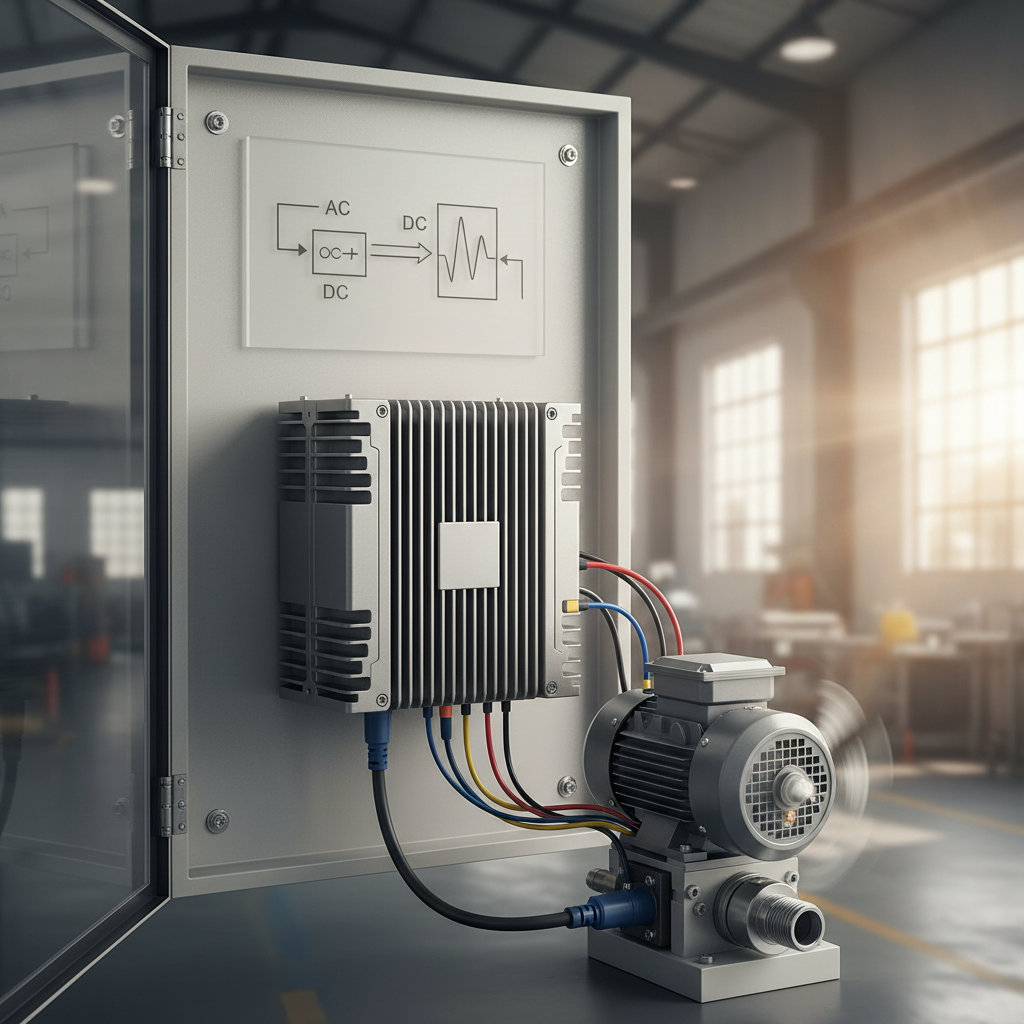

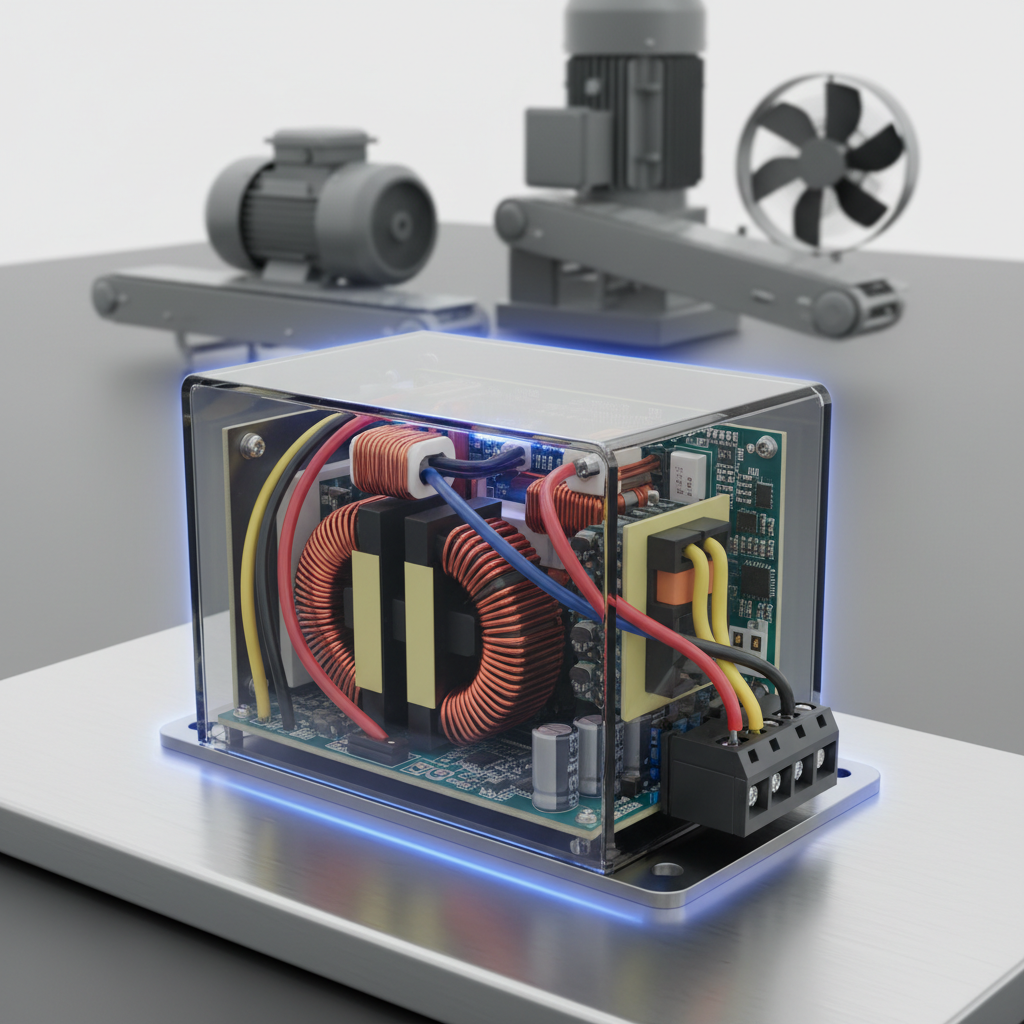

Single-phase Variable Frequency Drives (VFDs) are essential components in controlling the speed and torque of single-phase motors. At the core of their operation is a process called pulse width modulation (PWM). By varying the frequency of the output power supplied to the motor, these drives manipulate the motor speed effectively, allowing for precise control in various applications. The VFD converts the incoming AC power into DC power, which is then transformed back into AC power at the desired frequency, tailoring the motor's performance to specific operational requirements.

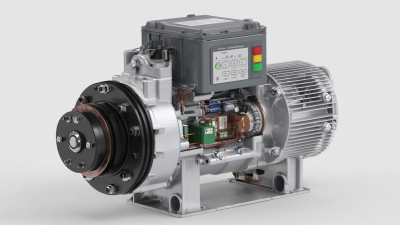

In addition to speed control, single-phase VFDs often incorporate advanced features such as soft start capabilities and overload protection. Soft start functionality reduces mechanical stress on the motor during startup, extending its lifespan and enhancing reliability. Meanwhile, overload protection safeguards the motor against damage due to excessive current, providing a crucial safety net for equipment while maintaining consistent performance. This technology allows industries using single-phase motors—like HVAC systems, conveyors, or small manufacturing machines—to achieve greater efficiency and adaptability in their operations.

Applications of Single Phase VFDs in Various Industries

Single phase variable frequency drives (VFDs) are increasingly utilized across various industries due to their ability to efficiently control the speed and torque of electric motors. In manufacturing, for instance, single phase VFDs are integral in applications such as conveyor systems and machine tools, allowing for precise control that maximizes efficiency and minimizes energy consumption. According to a report by Allied Market Research, the global variable frequency drive market is expected to reach $18.58 billion by 2027, indicating strong demand particularly in sectors relying on electric motor control.

In the HVAC industry, single phase VFDs are critical for optimizing energy usage in heating and cooling systems. By adjusting the fan and pump speeds to match varying load requirements, these drives can reduce energy consumption by up to 50%, contributing to significant cost savings and improved system performance. The U.S. Department of Energy estimates that VFDs can provide an energy savings of 40% compared to traditional control methods. This makes their adoption not only environmentally friendly but also economically advantageous for facilities looking to reduce operational costs while maintaining optimal performance in heating, ventilation, and air conditioning applications.

Choosing the Right Single Phase VFD for Your Needs

When selecting the right single phase VFD (Variable Frequency Drive) for your applications, it's essential to consider various specifications that align with your operational needs. Start by assessing the horsepower required for your motor, as this determines the size and capacity of the VFD you should choose. Additionally, consider the voltage rating; ensuring compatibility between the VFD and your power supply is crucial for efficient operation.

**Tip:** Always refer to the motor's nameplate data to understand its requirements fully. This will help in selecting the VFD with the right settings and to avoid potential damage to your equipment.

Furthermore, evaluate the control features of the VFD. Some applications may necessitate advanced control options, such as PID control or programmable logic. Identify whether you need built-in features like safety protocols or easy connectivity to external systems. These functionalities can greatly enhance the performance and adaptability of your drive in varying conditions.

**Tip:** Don’t overlook energy efficiency ratings; choosing a VFD designed for optimal energy use can lead to significant savings in operational costs, especially for long-term applications. Always ensure that you balance functionality with budget considerations while searching for the perfect fit for your needs.

What is a Single Phase VFD and How Does it Work for Your Applications - Choosing the Right Single Phase VFD for Your Needs

| Parameter | Details |

|---|---|

| Input Voltage | 110V to 240V AC |

| Output Voltage | Variable, typically up to input voltage |

| Control Method | V/f Control, Vector Control |

| Typical Applications | Fans, Pumps, Compressors, Conveyors |

| Power Range | Up to 10 HP |

| Environment | Indoor, dry locations |

| Protection Features | Over-voltage, Over-current, Over-temperature |

| User Interface | Keypad with Display or Remote Control Options |

Future Trends in Single Phase VFD Technology: What to Expect by 2025

As we look toward the future, Single Phase Variable Frequency Drives (VFDs) are poised for significant advancements by 2025. One of the most exciting trends is the integration of smart technologies, which will enable real-time monitoring and control of motor functions. This will allow for more precise adjustments to operational parameters, reducing energy consumption and enhancing efficiency. With the rise of the Internet of Things (IoT), VFDs will become increasingly interconnected, providing users with access to data analytics that can predict failure and optimize performance.

Moreover, the development of more compact and energy-efficient designs is on the horizon. As manufacturers strive to meet sustainability goals, Single Phase VFDs will likely incorporate advanced materials and innovative engineering techniques. This will not only reduce the physical footprint of these drives but also lower their environmental impact. As a result, businesses can expect to see more reliable, cost-effective solutions tailored for a wide range of applications, from HVAC systems to industrial automation, ultimately streamlining operations in various sectors.

Related Posts

-

Understanding the Importance of EMI Filters for VFD Applications in Modern Industry

-

5 Essential Reasons to Choose EMI Filters for Your Electronic Devices

-

5 Reasons Why Frequency Drive Controllers Are Essential for Global Procurement Success

-

7 Reasons Why the Best 220v VFD Single Phase is a Game Changer for Your Business

-

2025 Top Innovations in Single Phase Motor Inverter Technology for Energy Efficiency

-

How to Choose the Right 220V VFD Single Phase for Your Motor Applications