Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Why Motor Inverters Are Essential for Modern Electric Vehicles

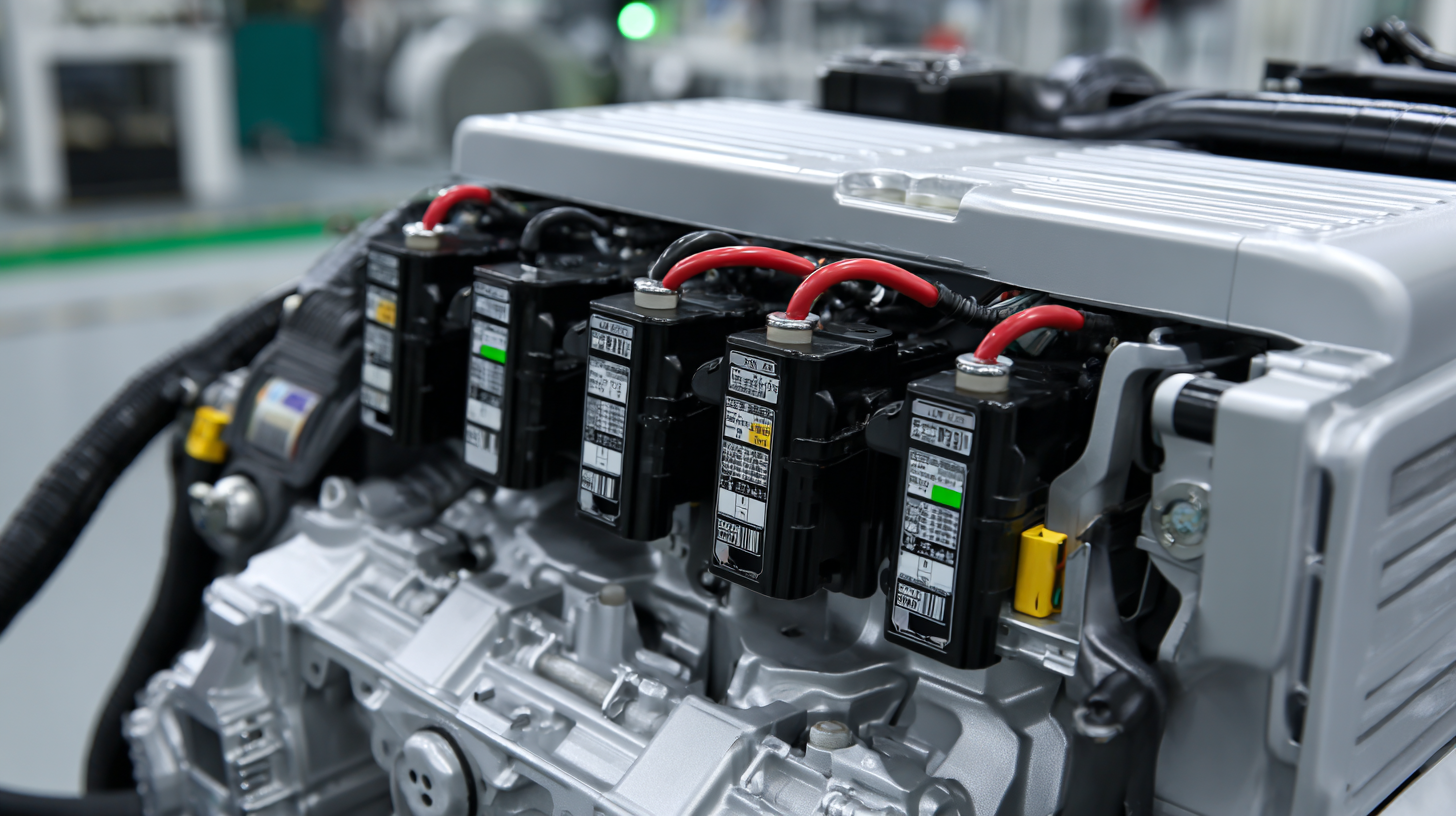

The rapid evolution of electric vehicle (EV) technology has underscored the critical role of motor inverters in enhancing vehicle performance and efficiency. Motor inverters serve as pivotal components in electric drivetrains, converting direct current (DC) from batteries into alternating current (AC) to power electric motors.

According to a recent report by MarketsandMarkets, the electric vehicle inverter market is projected to grow from USD 3.8 billion in 2020 to USD 11.9 billion by 2026, reflecting a CAGR of 20.8%. This surge is fueled by the increasing adoption of electric vehicles, with predictions estimating that by 2030, EVs will constitute over 30% of global car sales.

As manufacturers strive to improve vehicle range, performance, and charging efficiency, the integration of advanced motor inverters becomes indispensable, ensuring that modern electric vehicles meet consumer and regulatory demands for sustainability and operational excellence.

The Role of Motor Inverters in Enhancing Electric Vehicle Performance

Motor inverters play a crucial role in enhancing the performance of modern electric vehicles (EVs) by efficiently converting DC power from batteries into AC power that drives the vehicle’s electric motor. The traction inverter market is predicted to grow significantly, with advancements in technologies like IGBTs and MOSFETs driving this expansion. As manufacturers focus on improving power density and thermal management, innovations such as 1200 V CoolSiC MOSFETs have been instrumental in achieving enhanced power efficiency and heat dissipation, making them ideal for applications like EV chargers and inverters.

One notable trend in the EV sector is the increased localization of powertrain development, whereby manufacturers invest in local production capabilities to effectively respond to market demands. The electric two-wheeler powertrain market is expected to see substantial growth by 2032, fueled by ongoing investments in technology. Integrated solutions like multilevel inverters not only boost efficiency but also provide heightened reliability for electric vehicle applications.

Tips: Consider assessing the integration of self-excited wound rotor synchronous motors in your EV designs for improved versatility. Additionally, monitor the advancements in multilevel inverter technologies to stay ahead in efficiency gains—keeping an eye on power management systems could be equally beneficial.

Understanding the Technology Behind Motor Inverters for EVs

Motor inverters play a pivotal role in the functionality of modern electric vehicles (EVs) by converting direct current (DC) from the battery into alternating current (AC) for the electric motor. This conversion is crucial because the performance and efficiency of the motor directly impact the vehicle's overall performance, including acceleration, speed control, and energy consumption. As producers increasingly focus on optimizing energy management in EVs, understanding the technology behind motor inverters, particularly the use of Insulated Gate Bipolar Transistors (IGBTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), becomes essential.

The traction inverter market is experiencing significant growth, driven by advancements in these technologies. IGBTs are favored for their high efficiency and ability to handle more power, making them suitable for larger EV applications like passenger cars and industrial vehicles. Conversely, MOSFETs are increasingly used in smaller, lighter vehicles such as two-wheelers due to their rapid switching capabilities that enhance performance while minimizing energy loss. The balance between these technologies not only affects the inverter's size and cost but also influences the overall driving experience in electric vehicles, shaping the future landscape of sustainable transportation.

Key Benefits of Using Motor Inverters in Electric Vehicle Design

Motor inverters play a crucial role in the design and performance of modern electric vehicles (EVs), offering several key benefits that enhance their efficiency and functionality. One of the primary advantages of utilizing motor inverters is their ability to convert direct current (DC) from the vehicle’s battery into alternating current (AC), which is essential for powering the electric motors used in these vehicles. According to the International Energy Agency (IEA), integrating advanced inverter technologies can improve the overall energy efficiency of electric propulsion systems by 10-15%, a significant enhancement considering that energy consumption remains a critical factor for EV range.

Moreover, motor inverters enable sophisticated control over the vehicle's speed and torque, allowing for smooth acceleration and improved handling. This capability contributes to the overall driving experience, making electric vehicles not only efficient but also enjoyable to drive. The acceleration performance of an electric vehicle can increase by up to 30% with the implementation of high-performance inverters, as highlighted in a report by the Electric Power Research Institute (EPRI).

Tip: When considering an electric vehicle, pay attention to the inverter technology used, as it can directly influence the vehicle's performance and range. Also, look for models that incorporate regenerative braking systems, which work in tandem with motor inverters to recover energy and extend battery life.

Benefits of Motor Inverters in Electric Vehicle Design

The Future of Motor Inverters in Advancing Electric Mobility

As electric vehicles (EVs) continue to gain traction, motor inverters are emerging as pivotal components in the transition towards advanced electric mobility. These devices convert direct current (DC) from batteries into alternating current (AC) for electric motors, ensuring efficient energy use and enhanced performance. In the future, innovations in motor inverter technology will not only lead to increased range and speed but also contribute to the development of smarter EVs with improved energy management systems.

Tip: When considering an electric vehicle, pay attention to the specifications of its motor inverter. High-efficiency inverters can significantly enhance your driving experience by providing better acceleration and smoother handling.

Looking ahead, the integration of sophisticated algorithms and artificial intelligence into motor inverters will enable even more precise control over electric motors. This evolution will allow for tailored driving modes, regenerative braking capabilities, and overall improved vehicle dynamics. As manufacturers continue to invest in research and development, the role of motor inverters will undoubtedly be central to the future of electric mobility.

Tip: Stay informed about emerging inverter technologies that may offer faster charging times and extended battery life. These advancements will play a crucial role in the sustained growth of the electric vehicle market.

Challenges and Innovations in Motor Inverter Technology for EVs

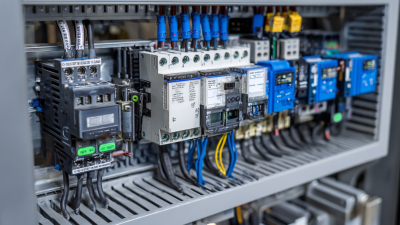

The evolution of motor inverter technology is critical for the advancement of electric vehicles (EVs). As reported by the International Energy Agency, the global stock of electric vehicles reached approximately 10 million in 2020, reflecting a burgeoning market that demands efficient and reliable motor inverters. These devices play a pivotal role in managing power flow between the battery and the electric motor, ensuring optimum performance and energy utilization. However, challenges such as thermal management, size reduction, and cost efficiency persist, requiring constant innovation.

To address these challenges, manufacturers are exploring advanced materials like silicon carbide (SiC) and gallium nitride (GaN), which can significantly enhance power density and efficiency. According to a report from MarketsandMarkets, the motor inverter market is anticipated to grow from $21.4 billion in 2021 to $29.2 billion by 2026, driven by innovations in semiconductor technology. This growth underscores the importance of investing in R&D to improve inverter capabilities, reducing energy losses and optimizing battery life.

Tips: To maximize the performance of your EV, consider the quality of the motor inverter and its components. Regular software updates can improve efficiency and responsiveness. Lastly, staying informed about technology upgrades can help you make better choices when purchasing or servicing your electric vehicle.

Related Posts

-

How to Select the Right Motor Inverter for Your Industrial Application

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

5 Reasons Why Frequency Drive Controllers Are Essential for Global Procurement Success

-

5 Amazing Facts About Motor Inverters You Should Know

-

How to Choose the Right 220V VFD Single Phase for Your Motor Applications

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance