Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

What is a Line Reactor and How Does It Work in Electrical Systems

In the realm of electrical systems, the efficiency and stability of power supplies are critical for ensuring optimal operational performance. Among the various components designed to enhance these attributes, the line reactor stands out as a vital element. Essentially, a line reactor is an inductive device used to mitigate voltage spikes and harmonic distortions in power circuits, serving as a protective barrier that safeguards both the equipment and the electrical supply network. By integrating a line reactor into an electrical system, operators can significantly reduce the risk of overcurrent situations, which can lead to equipment failure or reduced lifespan.

The functionality of a line reactor is rooted in its ability to smooth out fluctuations in current caused by sudden changes in load or power factor corrections. It achieves this by introducing a controlled amount of impedance into the circuit, effectively dampening transient voltages and harmonics that can adversely affect sensitive electrical devices. This leads to enhanced power quality and can result in substantial energy savings over time. Furthermore, the presence of a line reactor can improve the overall reliability of an electrical installation, making it an essential consideration for engineers and technicians tasked with designing and maintaining such systems. Understanding the operation and benefits of line reactors is therefore crucial for anyone involved in electrical engineering or system management.

What is a Line Reactor?

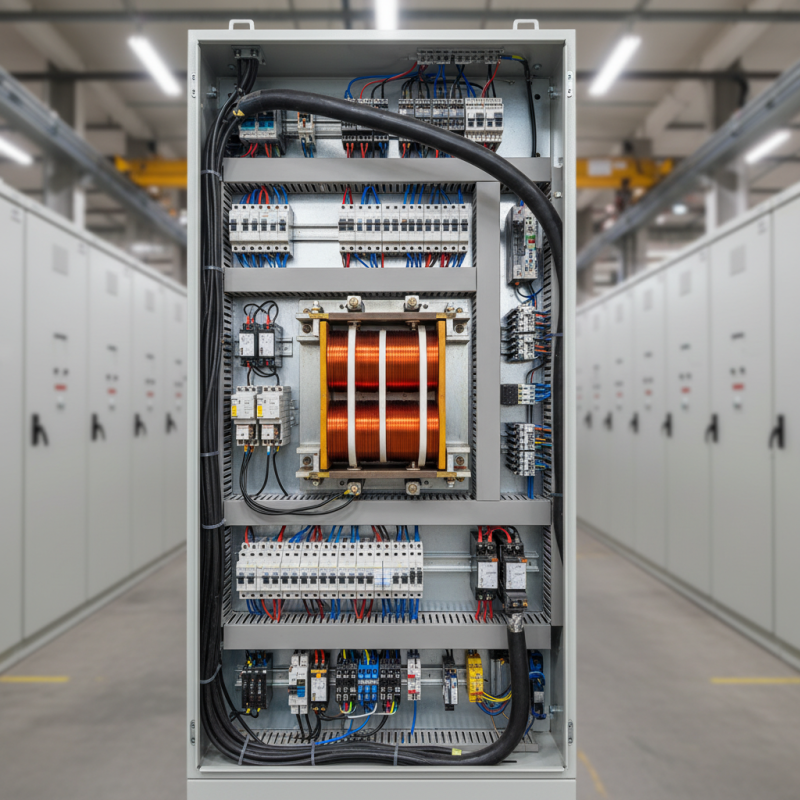

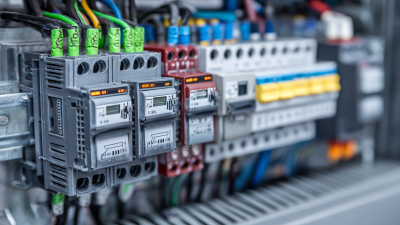

A line reactor is an electrical component that provides impedance in a circuit, primarily used to protect equipment from voltage transients and harmonics. Typically connected in series with power lines, line reactors serve to mitigate issues caused by harmonics generated by non-linear loads such as variable frequency drives (VFDs). By adding inductance to the system, they help to smooth out current fluctuations, thereby improving the overall power quality and reliability of electrical systems.

In operation, a line reactor works by absorbing excess voltage and limiting the current during transient conditions. This impedance not only reduces the inrush current during startup of motors but also enhances the performance of power electronic devices by providing a buffer against sudden changes in current. As a result, line reactors contribute to longer equipment life and reduced maintenance costs. They are essential components in ensuring the stability and efficiency of modern electrical systems, particularly in industrial and commercial applications where power quality is critically important.

Basic Principles of Line Reactors in Electrical Systems

Line reactors are essential components in electrical systems, designed to improve the performance and reliability of power electronics. Operating on the principle of electromagnetic induction, these devices are essentially inductors placed in series with the load. They function by mitigating issues such as voltage spikes, harmonics, and inrush currents, thus ensuring that the electrical system operates smoothly and efficiently.

The basic principle behind line reactors involves their ability to store energy in a magnetic field when current flows through them. This stored energy helps to counteract rapid changes in current and voltage, effectively dampening transients that can cause damage to sensitive equipment. By adding impedance to the circuit, line reactors also limit the flow of high-frequency harmonics generated by non-linear loads, thus improving the overall power quality of the system. This makes line reactors particularly beneficial in applications where electronic drives and variable frequency drives operate, ensuring stability and extending equipment lifespan.

What is a Line Reactor and How Does It Work in Electrical Systems

| Dimension | Description | Values |

|---|---|---|

| Inductance | The property of the reactor that opposes changes in current | 1 mH to 10 H |

| Voltage Rating | The maximum voltage the reactor can handle | 230V to 690V |

| Current Rating | The maximum current that can flow through the reactor | 5A to 2000A |

| Applications | Common uses in electrical systems | HVAC systems, motor drives, power supply systems |

| Benefits | Advantages of using line reactors | Reduced harmonic distortion, improved efficiency, protection against voltage spikes |

| Installation | How line reactors are typically installed in systems | In series with the motor or load, between the power source and the drive |

How Line Reactors Improve Power Quality

Line reactors are essential components in electrical systems, particularly in applications involving variable frequency drives (VFDs) and power conversion systems. These inductive devices are specifically designed to improve power quality by mitigating voltage spikes and harmonics generated by non-linear loads. By introducing a specific inductance in series with the power supply, line reactors help to smooth out the current and voltage waveforms, thereby reducing distortions that can negatively impact other equipment in the electrical distribution system.

One of the key benefits of line reactors is their ability to enhance system reliability and efficiency. By minimizing harmonic distortions, they contribute to improved overall power factor and reduce the risk of overheating in motors and transformers. Furthermore, line reactors can help protect sensitive electronic equipment from voltage transients and fluctuations, leading to a more stable operating environment. This improvement in power quality not only extends the lifespan of electrical components but also decreases maintenance costs and improves operational efficiency, making line reactors a vital aspect of modern electrical systems.

Applications of Line Reactors in Industry

Line reactors play a significant role in various industrial applications by providing critical support for electrical systems. Primarily used in substations and for motor control applications, these devices are essential for reducing harmonics and voltage spikes that can adversely affect the performance and longevity of equipment. According to a report from the International Electrotechnical Commission, nearly 30% of industrial motor failures are attributed to electrical disturbances, which highlights the necessity of line reactors in mitigating these risks.

In industries such as manufacturing, oil and gas, and water treatment, line reactors are indispensable for improving energy efficiency and reliability. For instance, in pump stations, line reactors help maintain smooth operation by minimizing inrush currents and ensuring stable voltage levels. A report by the U.S. Department of Energy indicates that implementing line reactors can enhance energy efficiency by up to 10%, significantly reducing operational costs and extending the life of electrical components. Additionally, in renewable energy sectors, line reactors are used to stabilize the power output from variable sources, facilitating a more efficient integration of energy into the grid. By addressing the challenges posed by electrical noise and transient voltages, line reactors serve as a crucial component for maintaining system integrity across various industrial applications.

Applications of Line Reactors in Electrical Systems

This chart illustrates the various applications of line reactors in electrical systems, highlighting the percentage frequency of their use across different industries. Line reactors are essential for improving power quality and protecting electrical equipment in these applications.

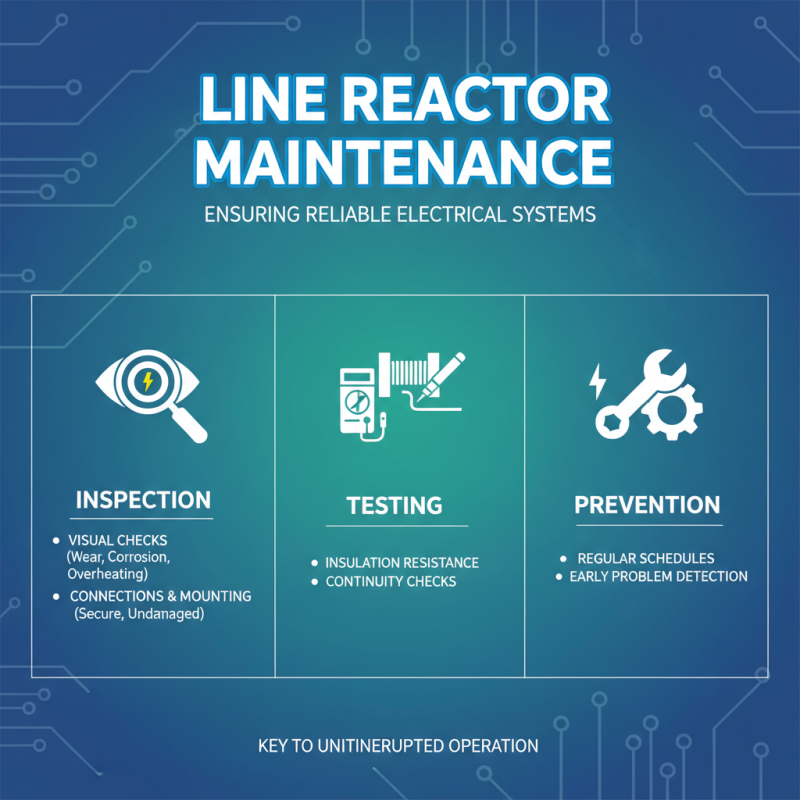

Maintenance and Troubleshooting of Line Reactors

Maintaining and troubleshooting line reactors is essential for ensuring their reliable operation within electrical systems. Regular inspection and maintenance practices should be established to monitor the condition of the reactor, which typically includes visual inspections for signs of wear, corrosion, or overheating. Operators should check the connections and mounting to ensure they are secure and free from damage, as loose connections can lead to increased resistance and potential failure. Additionally, periodic testing of the insulation resistance and continuity can help identify issues before they escalate.

When troubleshooting a line reactor, it is crucial to recognize the symptoms of malfunction, such as unexpected voltage fluctuations or increased harmonic distortion in the system. The first step in the troubleshooting process is to review operational data to pinpoint any abnormal performance indicators. If issues are identified, further investigation into the reactor's components, including the inductor windings and core, should be conducted. Utilizing clamp-on ammeters or oscilloscopes can aid in assessing the reactor's electrical parameters. Addressing any identified problems promptly will minimize downtime and enhance the overall efficiency of the electrical system.

Related Posts

-

Challenges When Choosing the Best Emi Filter for Vfd Applications

-

Understanding Single Phase VFD: Benefits, Applications, and Buying Guide

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

Top 10 Benefits of Using VFD Controllers in Industrial Applications

-

A Comprehensive Comparison of 220V VFD Single Phase Drives for Optimal Motor Performance