Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Exploring the Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings in Modern Applications

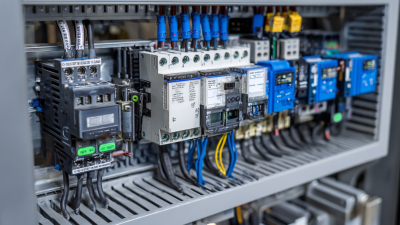

In recent years, the advancement of technology has revolutionized industrial applications, particularly through the integration of ATO single phase VFD (Variable Frequency Drives), which are pivotal in enhancing energy efficiency and driving cost savings. According to a report by the U.S. Department of Energy, the implementation of VFDs can lead to energy savings of 30-50% in fan and pump applications, while also providing better process control, reduced wear on equipment, and extended motor lifespan. The ATO single phase VFD not only optimizes power consumption by adjusting the motor speed according to demand but also contributes to a significant reduction in operational costs, providing a sustainable edge in competitive markets. As companies strive to reduce their carbon footprint while maintaining efficiency, understanding the implications of ATO single phase VFDs becomes increasingly crucial for modern applications.

Impact of ATO Single Phase VFD on Overall Energy Efficiency in Industrial Settings

The increasing demand for energy efficiency in industrial settings has prompted a significant shift towards the adoption of variable frequency drives (VFDs), particularly single-phase VFDs. ATO single-phase VFDs play a crucial role in optimizing energy consumption by allowing for precise control of motor speed and torque. This adaptability not only enhances the operational efficiency of electric motors but also leads to substantial cost savings in energy expenditures, which is particularly valuable in industries with high energy usage.

As industries strive to meet sustainability targets and reduce operational costs, integrating ATO single-phase VFDs can contribute to overall energy efficiency. In fact, reports forecast that the global market for variable frequency drives will exceed $21.9 billion by 2024, driven by the pressing need for energy-efficient solutions. The widespread implementation of these systems can help mitigate the approximately 50% of global electricity consumed by electric motors, showcasing their importance in achieving greener industrial practices while delivering economic benefits.

Key Cost Savings Associated with ATO VFD Implementation in Manufacturing Processes

Implementing ATO (Automatic Transfer Operator) single-phase Variable Frequency Drives (VFDs) in manufacturing processes can lead to significant cost savings. By enabling precise control over motor speed and torque, ATO VFDs allow manufacturers to optimize energy consumption during various operational phases. This optimization translates into reduced electricity bills, which is crucial for maintaining profitability in competitive markets. Additionally, because these drives minimize mechanical stress on equipment, there’s a decrease in maintenance costs and extended service life for motors and associated machinery.

Furthermore, ATO VFDs enhance overall process efficiency by improving production flexibility. With the ability to adjust speed and torque based on real-time production requirements, manufacturers can adapt quickly to changing demands without incurring excessive operational costs. This responsiveness not only leads to energy savings but also minimizes waste, since systems can be tailored to operate at their most efficient settings. Collectively, these factors highlight the financial advantages of integrating ATO single-phase VFD technology into modern manufacturing processes, ultimately fostering a more sustainable and cost-effective production environment.

Comparative Analysis: Single Phase VFD vs. Traditional Motor Systems in Energy Consumption

The transition from traditional motor systems to ATO single phase Variable Frequency Drives (VFDs) marks a significant shift in energy consumption practices within modern applications. Traditional motors operate at a constant speed, leading to wasted energy during periods of lower demand. In contrast, single phase VFDs intelligently adjust motor speed and torque according to real-time needs, resulting in decreased energy consumption and enhanced operational efficiency.

**Tips:** When considering a switch to a single phase VFD, assess your specific application requirements and load characteristics to ensure optimal compatibility. Investigating the initial installation costs is essential, but take note of the potential long-term savings on energy bills.

Moreover, a comparative analysis reveals that while traditional systems typically have lower initial costs, VFD-equipped systems present substantial savings over time due to their ability to reduce energy waste. Users can expect a quicker return on investment with VFDs, given the escalating costs of energy. Ultimately, the choice of implementing a single phase VFD can lead to significant financial benefits, as well as contribute to a more sustainable operational approach.

**Tips:** Monitor your energy usage before and after the VFD installation to quantify savings. Regularly maintenance checks will also help maximize the lifespan and efficiency of your new system.

Exploring the Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings in Modern Applications

| Application | Energy Consumption (kWh/year) | Cost of Energy ($/year) | Savings Compared to Traditional Motors (%) | Payback Period (months) |

|---|---|---|---|---|

| Pumping System | 15,000 | 1,800 | 30% | 12 |

| HVAC Systems | 20,000 | 2,400 | 25% | 14 |

| Conveyor Systems | 10,000 | 1,200 | 20% | 10 |

| Fan Systems | 12,000 | 1,440 | 22% | 11 |

| Industrial Mixers | 18,000 | 2,160 | 28% | 13 |

Real-World Case Studies Demonstrating ATO VFD Benefits in Energy Management

The integration of ATO single-phase variable frequency drives (VFDs) has been transformative in various industrial applications, particularly in enhancing energy management. Real-world case studies reveal significant energy savings and improved operational efficiency. For instance, a manufacturing facility reported a 30% reduction in energy consumption after implementing ATO VFDs for their motor controls. This aligns with findings from the Department of Energy, which states that using VFDs can lead to energy savings of 20-50% in motor-driven systems.

In agricultural applications, ATO VFDs have optimized irrigation systems, demonstrating the critical role of IoT in energy management. A case study highlighted an agricultural enterprise that reduced its energy costs by 25% through the deployment of smart VFDs connected to IoT platforms. These systems allowed real-time monitoring and adjustment of motor speeds based on environmental conditions, resulting in significant resource efficiency. Such innovations not only enhance productivity but also contribute to sustainability efforts in energy management, proving that the adoption of advanced technologies is vital for modern industrial applications.

Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings

Future Trends: Innovations in VFD Technology Driving Efficiency and Cost Reduction

The landscape of Variable Frequency Drives (VFDs) is undergoing a transformative shift, driven by advancements that significantly enhance both energy efficiency and cost-effectiveness in modern applications. Future trends indicate a growing integration of smart technologies, such as IoT and artificial intelligence, into VFD systems. These innovations enable real-time monitoring and predictive maintenance, reducing downtime and optimizing operational efficiency. By leveraging data analytics, businesses can adjust their energy consumption patterns, leading to substantial savings on utility bills.

Moreover, the development of next-generation VFDs emphasizes compact designs and improved materials that reduce energy losses. The incorporation of advanced algorithms allows for smoother operation and better control of motor speeds, which not only enhances performance but also extends the lifespan of equipment. With these technological strides, industries can expect not only immediate cost reductions but also long-term sustainability benefits. As these trends continue to evolve, VFDs will play an integral role in the push for greener practices and enhanced operational efficiencies across various sectors.

Related Posts

-

7 Reasons Why the Best 220v VFD Single Phase is a Game Changer for Your Business

-

Unlocking Efficiency in Industrial Applications How to Use the Best Single Phase to 3 Phase Converter VFD

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

Exploring VFD Drives Industry Trends at the 2025 China 138th Canton Fair

-

Discover How China is Revolutionizing Global Markets with Best 220v VFD Single Phase Solutions

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance