Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Discover High-Quality 220V VFD Single Phase Solutions from Leading Chinese Manufacturers

In today's rapidly evolving industrial landscape, finding reliable suppliers for vital components such as 220V VFD single phase solutions is crucial for businesses aiming to enhance efficiency and productivity. With the growing demand for variable frequency drives, particularly in single-phase applications, leading Chinese manufacturers have risen to prominence, offering high-quality products that cater to diverse needs. However, navigating the multitude of options available can be daunting. This blog aims to guide you through the essential considerations for identifying top-notch suppliers in the competitive market of 220V VFD single phase technology. By focusing on key factors like product quality, supplier reputation, and customer support, we will equip you with the necessary tools to make informed decisions and ultimately improve your operational capabilities.

Understanding the Challenges of Using Single Phase VFDs in 220V Applications

The utilization of single-phase VFDs (Variable Frequency Drives) in 220V applications presents several challenges that manufacturers and users must address. According to a recent industry report by Research and Markets, the demand for efficient motor control solutions has grown by 15% annually, which highlights the importance of optimizing single-phase VFDs to meet market needs. One primary challenge is the limited power output capacity compared to three-phase systems, which can hinder performance in larger applications. Additionally, single-phase VFDs often exhibit lower efficiency and thermal management issues, necessitating advanced design strategies to enhance reliability.

The utilization of single-phase VFDs (Variable Frequency Drives) in 220V applications presents several challenges that manufacturers and users must address. According to a recent industry report by Research and Markets, the demand for efficient motor control solutions has grown by 15% annually, which highlights the importance of optimizing single-phase VFDs to meet market needs. One primary challenge is the limited power output capacity compared to three-phase systems, which can hinder performance in larger applications. Additionally, single-phase VFDs often exhibit lower efficiency and thermal management issues, necessitating advanced design strategies to enhance reliability.

Tip: When considering single-phase VFDs, it's crucial to assess the specific application requirements, including load characteristics and environmental conditions, to ensure the right solution is implemented.

Another significant issue is the compatibility of single-phase VFDs with various motor types. Not all induction motors can efficiently run on single-phase drives due to inherent design constraints, potentially leading to inefficient operation or even motor damage. The global market for industrial VFDs is projected to reach $25 billion by 2027, according to Allied Market Research, which indicates a growing recognition of the need for versatile VFD solutions.

Tip: Always consult with manufacturer specifications and guidelines to confirm compatibility with existing systems and ensure optimal performance from single-phase drives.

Common Issues Faced by Users of 220V VFD Solutions

When utilizing 220V Variable Frequency Drives (VFDs), users often encounter specific challenges that can impact their overall experience and system performance. One common issue is the improper sizing of the VFD. Selecting a drive that is either too small or too large for the application can lead to inefficiencies and potential equipment failure. It’s critical to ensure that the VFD matches the motor's specifications, including its voltage and current ratings, to optimize control and prolong the lifespan of both the motor and the drive.

Another prevalent problem users face is related to electrical noise and harmonic distortion. These disturbances can arise from the switching processes within the VFD, affecting surrounding equipment and leading to operational instability. Users often need to implement additional measures such as filters or shielding to minimize these effects. Proper installation and a solid understanding of the electrical environment can significantly mitigate these issues and enhance system reliability, allowing for smoother operation of machinery powered by high-quality 220V VFD solutions from leading manufacturers.

Evaluating Performance: Potential Drawbacks of Chinese-Made VFDs

When considering the adoption of Variable Frequency Drives (VFDs) produced by Chinese manufacturers, it's essential to conduct a thorough evaluation of their performance. While many Chinese VFDs offer competitive pricing and innovative features, reports from the International Electrotechnical Commission (IEC) indicate that they may not always meet the highest reliability standards expected in critical industrial applications. A study in 2022 highlighted that approximately 20% of users experienced performance issues due to inadequate cooling systems and lower-grade electronic components, which often result in increased maintenance costs.

Additionally, a report published by the Global Research and Data Analysis (GRDA) noted that while Chinese VFDs have improved significantly in quality over the past decade, they still lag behind their European counterparts in terms of energy efficiency. The study revealed that the average efficiency rating for Chinese-made VFDs was around 85%, compared to over 92% for leading European brands. This discrepancy can lead to higher operational costs in the long term, making it crucial for businesses to weigh initial cost savings against potential efficiency losses and maintenance requirements when choosing their VFD solutions.

Discover High-Quality 220V VFD Single Phase Solutions from Leading Chinese Manufacturers

| Parameter | Specification | Performance | Potential Drawbacks |

|---|---|---|---|

| Input Voltage | 220V | Compatible with Standard Drives | Limited Availability in Remote Areas |

| Output Power | 0.5 kW - 15 kW | Wide Power Range | Power Fluctuation under Load |

| Control Method | V/F Control, Vector Control | Excellent Speed Control | Complex Setup for Advanced Features |

| Efficiency | Up to 95% | High Energy Savings | Heat Generation in Extended Use |

| Features | Overload Protection, PID Control | Comprehensive Functionality | User Manual Clarity Issues |

Troubleshooting Solutions for Typical Problems with Single Phase VFDs

When dealing with single-phase Variable Frequency Drives (VFDs), troubleshooting common issues is crucial for maintaining optimal performance. One prevalent problem is the impact of common-mode voltage (CMV) on motor windings, which can lead to bearing currents and electromagnetic interference (EMI). Properly addressing these concerns requires a clear understanding of how VFDs, particularly those using pulse width modulation (PWM), operate. The generated voltage can sometimes deviate significantly from ideal conditions, often resulting in damage to motor insulation and premature failures.

Furthermore, the increasing sophistication of single-phase applications presents both opportunities and challenges for manufacturers and OEMs. As the market grows, identifying potential motor issues associated with VFDs becomes more critical. Operators should be vigilant about common motor concerns like overheating and noise, which are exacerbated by inappropriate VFD settings or environmental factors. By implementing tailored troubleshooting solutions, users can enhance the longevity and reliability of their systems, ensuring that high-quality 220V VFDs operate efficiently in various industrial applications.

Best Practices for Preventing Issues with 220V VFD Installations

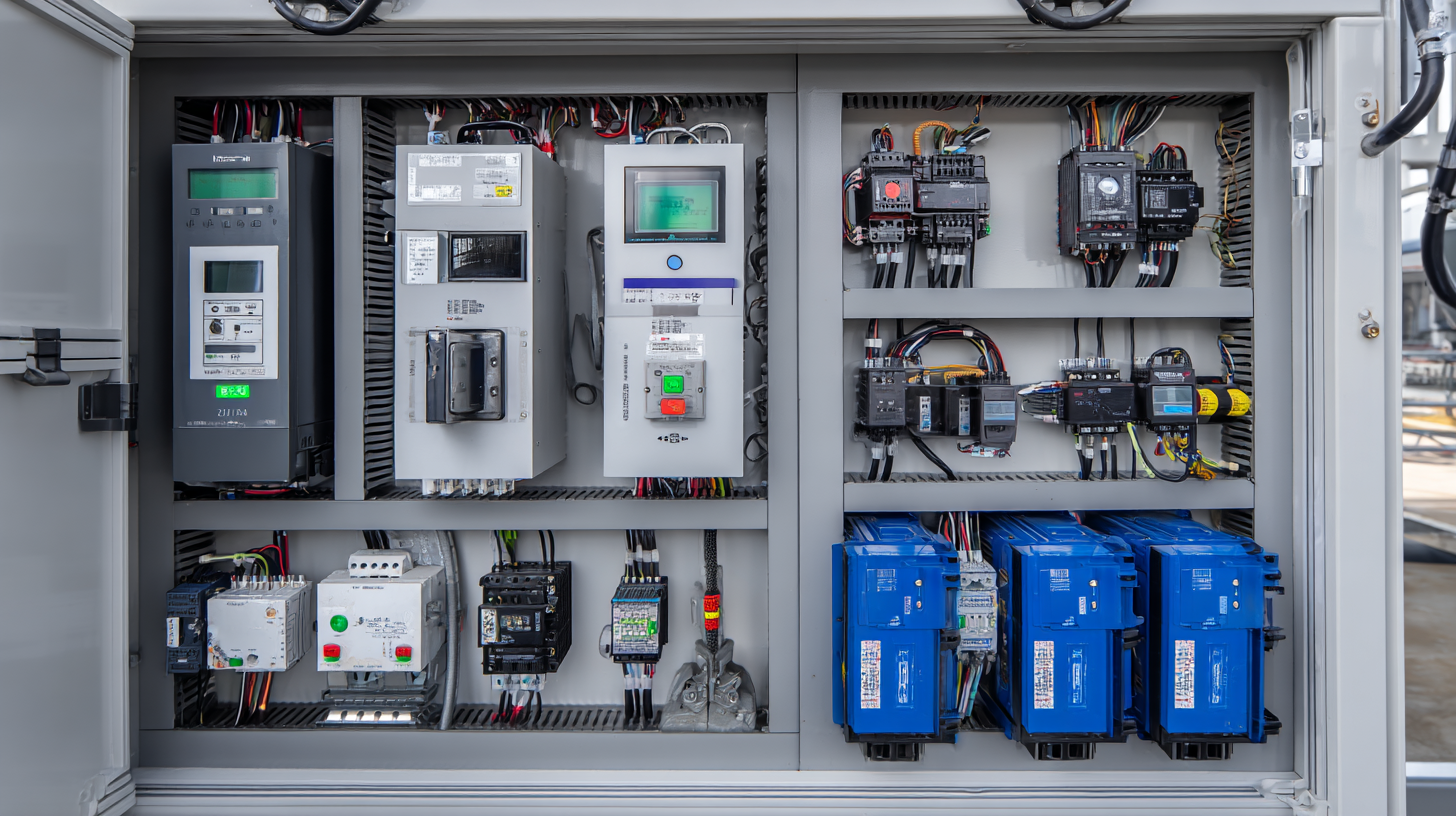

When installing 220V Variable Frequency Drives (VFDs), proper planning and adherence to best practices can significantly minimize issues that could arise during operation. First and foremost, it is crucial to ensure the electrical compatibility of the VFD with the existing system. This involves checking the voltage levels, current ratings, and frequency settings. Additionally, installing appropriate filters can help mitigate electromagnetic interference, which is particularly important in environments with sensitive electronics.

Another vital aspect of a successful 220V VFD installation is proper cooling and ventilation. VFDs generate heat during operation, and without sufficient airflow, overheating can lead to failures or reduced performance. Placing the drive in a location that allows for adequate cooling or using external cooling systems can prevent thermal issues. Regular maintenance and inspections are also essential to identify potential problems early, allowing for timely interventions that can prolong the lifespan of the VFD and maintain optimal operational efficiency. By following these best practices, users can enhance the reliability and effectiveness of their 220V VFD installations.