Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

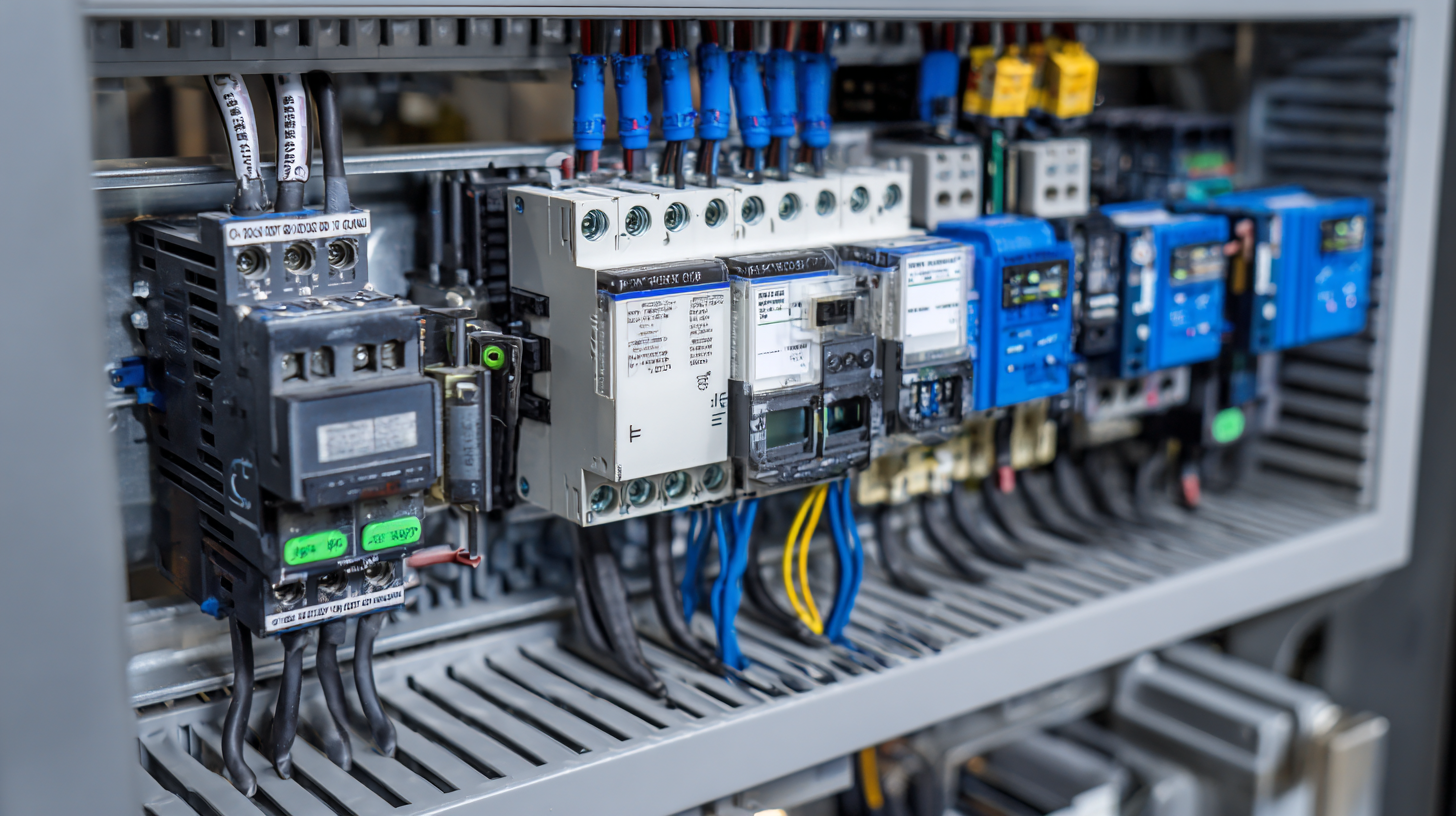

In the quest for enhanced performance and efficiency in various industrial applications, the traditional frequency drive controller has long served as a cornerstone of motor control technology. However, as industries evolve and the demand for innovative solutions grows, it becomes essential to explore alternatives that can not only match but surpass the capabilities of conventional controllers. This blog delves into groundbreaking approaches and technologies that promise to redefine performance standards, offering a range of solutions tailored for specific needs. By examining these innovative alternatives, we aim to provide valuable insights into how businesses can leverage these advancements to improve operational efficiency, reduce energy consumption, and achieve greater flexibility in their processes. Join us as we uncover the potential of next-generation technologies and their implications for the future of motor control.

Challenges Faced by Traditional Frequency Drive Controllers in Modern Applications

Traditional frequency drive controllers have long been the backbone of motor control in various industrial applications. However, as technology continues to advance, these controllers face significant challenges that hinder their effectiveness in modern settings. One of the primary issues is their limited adaptability to rapidly changing operational environments. With the rise of automation and smart manufacturing, the need for more flexible, real-time control mechanisms has become apparent. Many frequency drive controllers lack the capability to respond promptly to dynamic load changes, resulting in inefficiencies and increased wear on equipment.

Another challenge lies in their energy consumption profiles. While frequency drives are designed to optimize motor performance, they often fall short in achieving maximum energy efficiency, especially in applications with varying loads. This not only increases operational costs but also poses environmental concerns as industries move towards greener practices. Additionally, traditional controllers can struggle with integration into modern digital ecosystems, making it difficult to leverage data analytics and predictive maintenance strategies. As industries seek innovative solutions, the exploration of alternative technologies that address these challenges is becoming increasingly vital for enhancing performance and sustainability in motor control applications.

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance - Challenges Faced by Traditional Frequency Drive Controllers in Modern Applications

| Application Area | Challenges with Traditional Controllers | Innovative Alternatives | Benefits of Alternatives |

|---|---|---|---|

| Industrial Automation | Limited adaptability to new technologies | Smart IoT Controllers | Real-time data processing and analytics |

| Renewable Energy Systems | Inefficiencies in energy conversion | Advanced Energy Management Systems | Improved energy efficiency and integration |

| HVAC Systems | High energy consumption | Variable Speed Drives with AI | Enhanced comfort and lower operating costs |

| Water Treatment | Inflexibility to changing loads | Adaptive Control Systems | Optimized resource utilization and reliability |

| Transportation | Slow response to dynamic conditions | Dynamic Speed Controllers | Enhanced performance and safety measures |

Emerging Technologies: A Look at Next-Gen Control Systems

Emerging technologies are transforming control systems across various industries, showcasing how advanced methodologies can enhance operational efficiency and effectiveness. The Army's Next Generation Command and Control framework epitomizes this shift, leveraging a robust architecture designed to process operational data seamlessly. This innovative approach is grounded in responsiveness and adaptability, enabling commanders to make informed decisions swiftly in dynamic environments, where traditional systems might falter.

In the manufacturing sector, next-generation automation technologies are reshaping educational paradigms through immersive learning experiences that integrate Industry 4.0 and 5.0 concepts. By focusing on a Smart Factory learning environment, educational institutions are preparing a new generation of engineers and operators equipped with the skills needed to thrive in increasingly automated settings. Reports indicate that smart buildings utilizing IoT and machine learning can reduce operational costs by up to 30%, highlighting the efficiency gains realized through data-driven strategies that enhance performance while minimizing waste.

Moreover, advancements in full-authority digital engine control systems signal significant progress in aviation, where digital technologies are being harnessed to enhance reliability and precision in engine management. This shift towards digital innovations is reflected in various sectors, as industries aim to improve operational capabilities while addressing contemporary challenges related to sustainability and efficiency. The integration of cutting-edge technologies across these domains illustrates a collective movement towards innovative, next-gen control systems that promise to redefine performance benchmarks.

Comparative Analysis of Alternative Controller Solutions

As industries increasingly seek to optimize energy efficiency and enhance operational performance, traditional frequency drive controllers are being scrutinized in favor of innovative alternatives. A comparative analysis reveals several promising solutions that can outperform conventional systems. For instance, a recent study by the International Energy Agency (IEA) suggests that implementing advanced control algorithms, such as model predictive control (MPC), can lead to energy savings of up to 20% in motor-driven applications compared to standard frequency drives.

Additionally, the rise of digital technologies has propelled the adoption of programmable logic controllers (PLCs) with integrated smart sensing capabilities. According to a report by Research and Markets, this segment is expected to grow at a compound annual growth rate (CAGR) of 8.1% from 2021 to 2026. These advanced PLCs not only provide enhanced monitoring and control but also facilitate real-time data analytics, allowing businesses to make informed decisions that can further optimize their energy consumption and operational efficiency.

Furthermore, emerging technologies such as IoT-enabled controllers are paving the way for more interconnected systems. A McKinsey study highlights that IoT applications in manufacturing could contribute up to $1.2 trillion in value by 2025, showcasing the immense potential of these alternative solutions in transforming performance outcomes across various sectors.

Case Studies: Success Stories Using Innovative Alternatives

As industries increasingly seek efficiency and performance enhancements, innovative alternatives to traditional frequency drive controllers have emerged as viable solutions. One notable case study is the adoption of direct torque control (DTC) in the automotive sector, which has demonstrated a remarkable reduction in energy consumption. According to the International Energy Agency (IEA), DTC can improve efficiency by up to 30% compared to conventional methods. This not only cuts operational costs but also aligns with global sustainability targets, showcasing how technological advancements can drive both performance and environmental responsibility.

Another compelling example comes from the food and beverage industry, which has successfully integrated model predictive control (MPC) systems to optimize process automation. A report by the Food Processing Association indicates that facilities using MPC have experienced a 20% increase in throughput while maintaining product quality. By leveraging advanced algorithms, these systems adjust parameters in real-time, leading to enhanced operational agility and significant cost savings. As industries embrace such innovative technologies, the case studies reflect a broader trend towards smarter, more energy-efficient practices that are reshaping the landscape of industrial performance.

Future Trends in Drive Control Technology and Their Impact on Performance

The future of drive control technology is poised for significant transformation, driven by innovative alternatives to traditional frequency drive controllers. As industries increasingly prioritize energy efficiency, advancements in high-efficiency, smart, and integrated motor drives are emerging as key trends. These innovations not only enhance performance but also align with global sustainability goals, especially in electric vehicle propulsion systems.

The future of drive control technology is poised for significant transformation, driven by innovative alternatives to traditional frequency drive controllers. As industries increasingly prioritize energy efficiency, advancements in high-efficiency, smart, and integrated motor drives are emerging as key trends. These innovations not only enhance performance but also align with global sustainability goals, especially in electric vehicle propulsion systems.

Tip: When considering upgrades to drive systems, focus on smart control technologies that use real-time data to optimize performance and reduce energy consumption. This can lead to both operational cost savings and improved environmental impact.

Moreover, the ongoing evolution of communication technologies, particularly with the advent of 6G and satellite internet, will further enhance the capabilities of drive control systems. This integration of advanced communication networks will enable more responsive and intelligent control mechanisms, giving rise to a new era of automation and efficiency in various industries.

Tip: Stay informed about the latest trends in communication technology, as they will play a crucial role in shaping the future of drive control systems. Implementing cutting-edge solutions can help maintain a competitive edge in your sector.