Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Understanding the Importance of EMI Filters for VFD Applications in Modern Industry

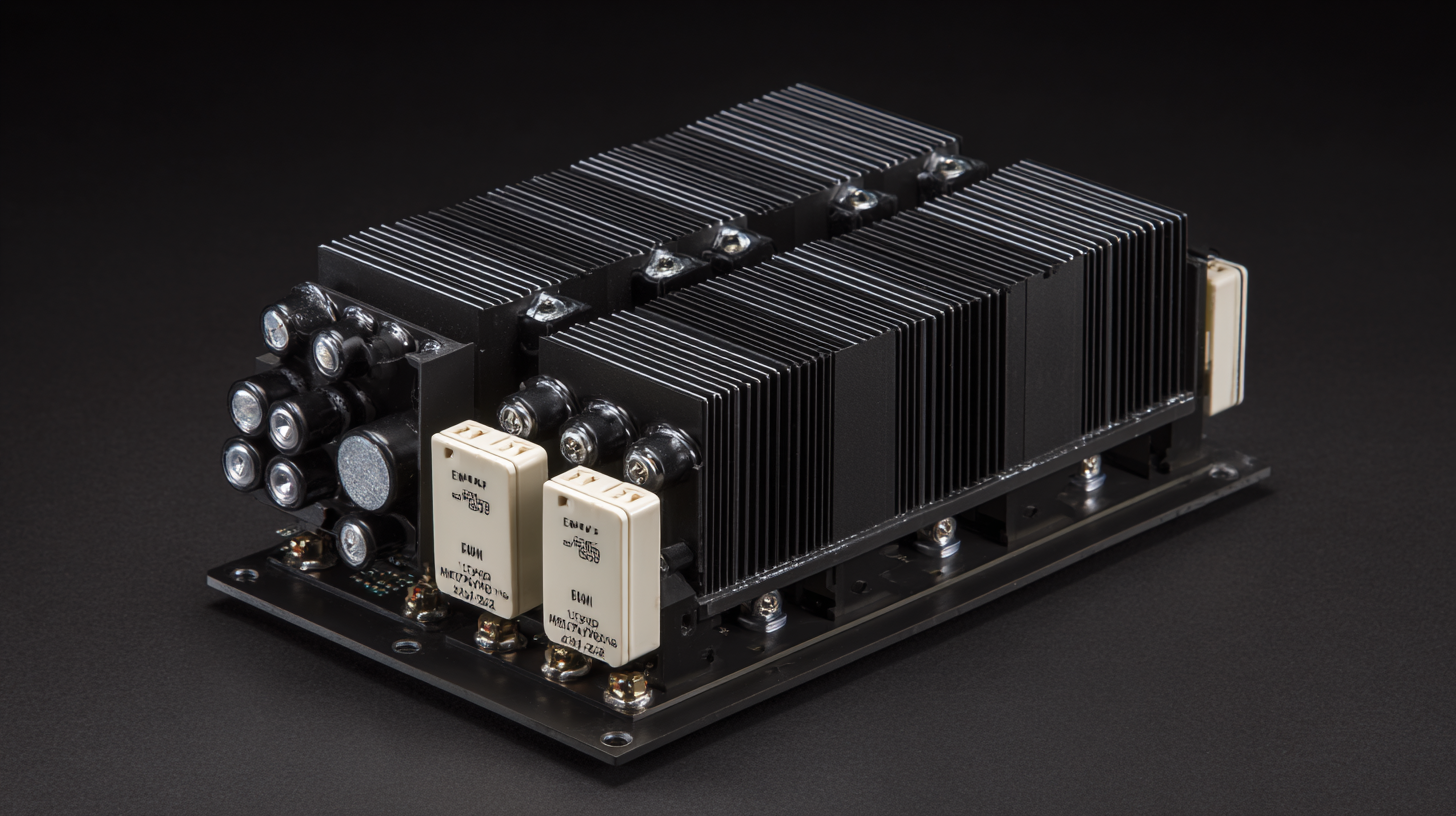

In modern industrial applications, the implementation of Variable Frequency Drives (VFDs) has revolutionized the control and efficiency of electric motors. However, these advancements come with the challenge of electromagnetic interference (EMI), which can lead to operational disruptions and equipment failure. According to a recent report from Research and Markets, the global market for EMI filters is projected to reach USD 2.1 billion by 2026, underscoring the growing importance of ensuring signal integrity within VFD systems. An effective EMI filter for VFD not only mitigates noise that can affect performance but also enhances the longevity of equipment by protecting sensitive components from voltage spikes. As industries strive for greater energy efficiency and compliance with stringent regulations, understanding the critical role of EMI filters becomes essential for optimizing VFD applications and safeguarding operational reliability.

The Role of EMI Filters in Enhancing VFD Efficiency and Longevity

In modern industrial applications, particularly with Variable Frequency Drives (VFDs), the role of Electromagnetic Interference (EMI) filters cannot be overstated. These filters are essential for enhancing the efficiency and longevity of VFD systems by effectively mitigating electrical noise, voltage spikes, and harmonics generated during the operation. Research indicates a growing market for EMC filtration, predicted to expand significantly between 2025 to 2030, as industries seek to improve power quality and minimize the adverse effects of EMI on their control systems.

Tips: When selecting EMI filters for VFD installations, consider options such as 1-phase and 3-phase EMC filters, which are designed to handle specific load requirements and provide optimal interference suppression. Additionally, integrating passive power quality filters can further enhance the stability and reliability of systems where Variable Speed Drives (VSDs) are utilized, especially in HVAC settings where electromagnetic disturbances are prevalent.

Moreover, recent advancements in power EMI filter technologies have led to the introduction of modular designs that comply with military standards, showcasing the versatility and application of these filters across various industries. With the global EMC filtration market projected for robust growth, investing in high-quality EMI filters will not only improve operational efficiency but also extend the lifespan of critical industrial equipment.

Impact of Electromagnetic Interference on VFD Performance and Reliability

Electromagnetic interference (EMI) presents a significant challenge in variable frequency drive (VFD) applications across modern industries. This interference can disrupt the operation of VFDs, leading to performance inefficiencies and reducing the overall reliability of industrial systems. VFDs, which are essential for controlling motor speed and torque, can be particularly sensitive to EMI, resulting in erratic functioning and potential damage to components. The presence of EMI can cause unpredictable voltage spikes, leading to overheating and premature failure of the drive and connected equipment.

To mitigate the adverse effects of EMI, the implementation of EMI filters becomes crucial. These filters act as barriers to unwanted electromagnetic signals, thus protecting the VFD and maintaining optimal operational stability. By effectively reducing the levels of conducted and radiated noise, EMI filters enhance the performance of VFDs, allowing for smoother motor operation and extending the lifespan of electrical components. The integration of high-quality EMI filters not only improves the reliability of VFD systems but also ensures conformity with regulatory standards, thereby safeguarding sensitive processes within modern industrial environments.

Impact of EMI on VFD Performance and Reliability

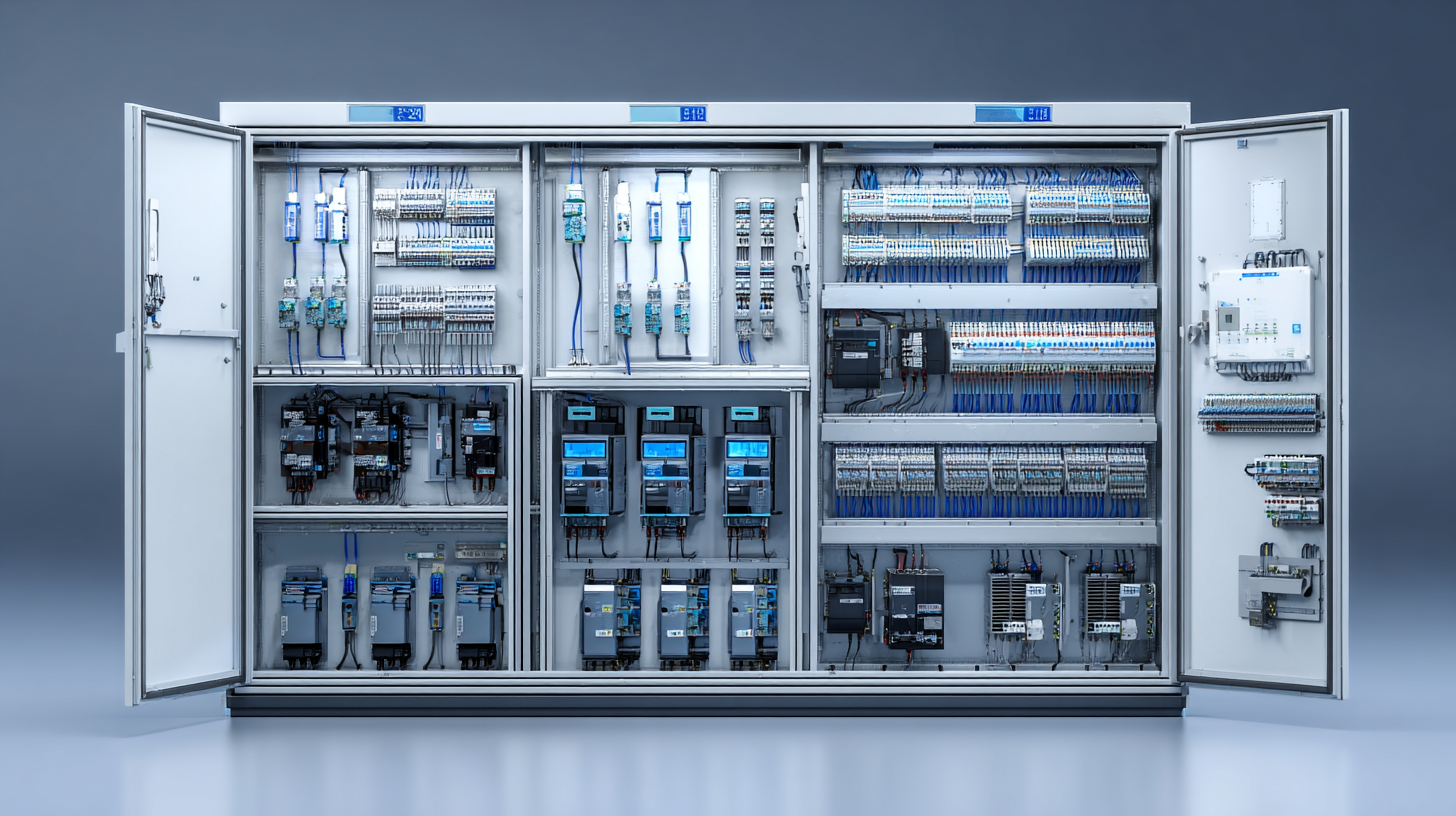

Industry Standards and Regulations Governing EMI Filter Usage in VFD Systems

In modern industrial applications, where Variable Frequency Drives (VFDs) play a crucial role in enhancing efficiency and control, the significance of Electromagnetic Interference (EMI) filters cannot be overstated. The growing use of VFD systems has prompted the development of industry standards, such as SEMI E176-1017, which emphasize the importance of managing EMI not just on a device-by-device basis, but holistically across entire manufacturing environments. This shift in focus is essential for ensuring the stable operation of sensitive electronic equipment within the tightly integrated systems typical in today’s factories.

As industries increasingly rely on clean power solutions, compliance with established regulations for EMI filter usage is paramount. Such standards help mitigate the adverse effects of electromagnetic interference, which can hinder performance and reliability. With a projected growth in the clean power VFD market, set to reach USD 1.52 billion by 2030, adhering to these regulations will be critical for manufacturers aiming to integrate advanced technologies while minimizing disruptions caused by EMI. By understanding and implementing proper EMI filtering solutions, industries can maintain operational integrity and foster innovation in their processes.

Cost-Benefit Analysis: Investing in EMI Filters for VFD Applications

Investing in EMI filters for Variable Frequency Drives (VFDs) is a strategic decision that impacts both operational efficiency and long-term cost management. By mitigating electromagnetic interference, these filters enhance the reliability of VFDs, which are critical in controlling motor speed and improving energy efficiency. The initial investment in EMI filters can be seen as a cost-effective measure when compared to potential losses from equipment failures or malfunctions caused by interference. The resultant increase in equipment lifespan and performance can offset the initial outlay.

Investing in EMI filters for Variable Frequency Drives (VFDs) is a strategic decision that impacts both operational efficiency and long-term cost management. By mitigating electromagnetic interference, these filters enhance the reliability of VFDs, which are critical in controlling motor speed and improving energy efficiency. The initial investment in EMI filters can be seen as a cost-effective measure when compared to potential losses from equipment failures or malfunctions caused by interference. The resultant increase in equipment lifespan and performance can offset the initial outlay.

Moreover, the presence of EMI filters in VFD applications can lead to reduced maintenance costs and downtime. In industries where continuous operation is crucial, any disruption can translate into significant financial losses. By integrating EMI filters, companies can ensure smoother operation of their electrical systems, leading to fewer service interruptions. This proactive approach not only safeguards the integrity of machinery but also contributes to a more stable and predictable operating environment, making the case for EMI filters an essential consideration in modern industrial applications.

Case Studies: Successful Implementation of EMI Filters in Modern Industrial Settings

In modern industrial settings, the successful implementation of EMI (Electromagnetic Interference) filters in VFD (Variable Frequency Drive) applications has proven critical in enhancing system performance and reliability. With the rise of advanced industrial practices, such as wireless data interconnection in slip ring applications operating at 60GHz, manufacturers are increasingly focusing on integrating EMI filters to mitigate disruptions that can affect sensitive equipment. These filters serve not only to protect the integrity of the electrical systems but also ensure seamless communication within the industrial network, which is essential for achieving operational efficiency.

Case studies highlight various successful implementations where incorporation of EMI filters has led to significant reductions in electrical noise, resulting in improved equipment longevity and decreased downtime. For instance, industries adopting these filters observed marked enhancements in data transmission accuracy and real-time monitoring capabilities, aligning well with the principles of device interconnectivity and information transparency that drive the Fourth Industrial Revolution. As digital manufacturing continues to evolve, the role of EMI filters in safeguarding advanced industrial applications will undoubtedly grow in importance.

Related Posts

-

Top Strategies for Implementing EMI Filters in VFD Applications for Enhanced Performance

-

Exploring VFD Drives Industry Trends at the 2025 China 138th Canton Fair

-

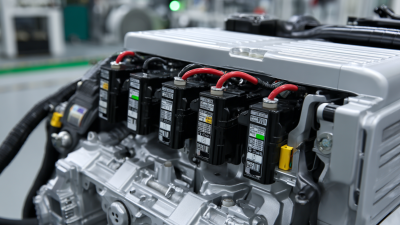

Exploring the Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings in Modern Applications

-

Why Motor Inverters Are Essential for Modern Electric Vehicles

-

A Comprehensive Comparison of 220V VFD Single Phase Drives for Optimal Motor Performance

-

10 Best VFD Controllers You Need to Know for Optimal Performance