Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

2025 How to Choose the Right VFD Controller for Your Motor Applications

In the realm of motor applications, selecting the appropriate Variable Frequency Drive (VFD) controller is paramount for optimizing performance and efficiency. As industry expert James Reynolds once stated, "The right VFD controller not only enhances the motor's operation but also contributes significantly to energy savings and longevity." This underscores the importance of a thoughtful approach when choosing a VFD controller tailored to specific needs.

Understanding the various configurations, functionalities, and compatibility of VFD controllers can greatly impact the overall effectiveness of motor-driven systems. Whether in manufacturing, HVAC, or any industrial sector, the role of a VFD controller in managing speed and torque remains critical. It is essential for engineers and decision-makers to evaluate their unique applications thoroughly, ensuring the selected controller aligns with operational goals.

As technology continues to evolve, the selection process for a VFD controller will inevitably become more complex. Incorporating factors such as scalability, control algorithms, and energy efficiency ratings can help streamline this decision. In this article, we will delve deeper into these considerations and guide you through the essential steps to effectively choose the right VFD controller for your motor applications.

Understanding VFD Controllers and Their Importance in Motor Applications

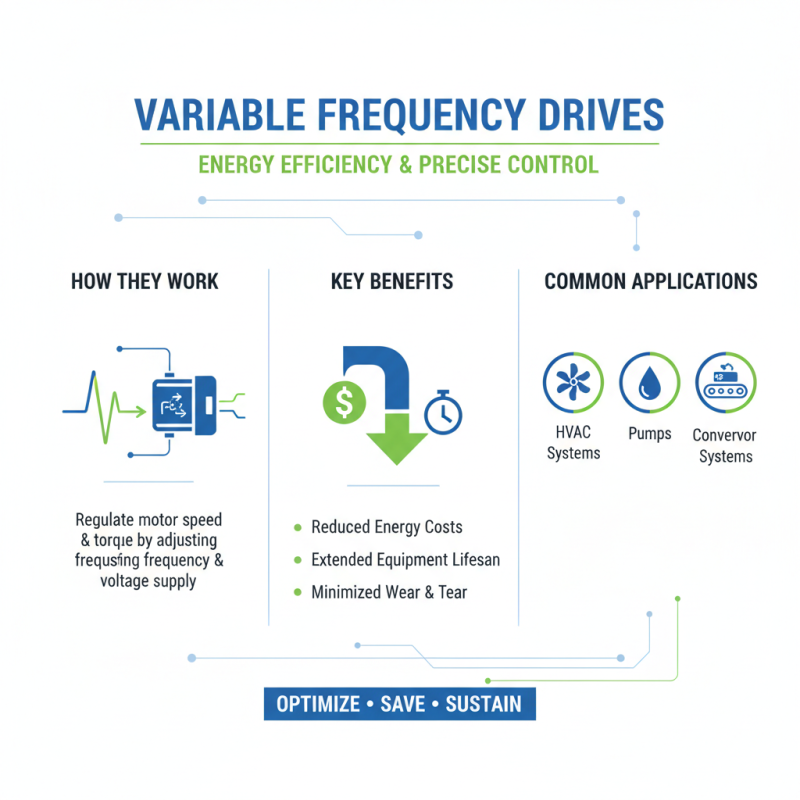

Variable Frequency Drives (VFDs) play a crucial role in optimizing the performance of motor applications across various industries. A VFD controller adjusts the frequency and voltage supplied to an electric motor, allowing for precise control over motor speed and torque. This is particularly important in applications that require varying speed, as it enhances efficiency and reduces energy consumption. Moreover, by managing motor operation more effectively, VFDs can lead to extended equipment life and lowered maintenance costs, making them a vital component of modern motor systems.

Understanding the functionality and advantages of VFD controllers is essential for selecting the right one for specific applications. Factors to consider include the type of motor, the required speed range, and the load characteristics. By comprehensively assessing these parameters, users can ensure that the VFD controller will not only meet the operational demands but also maximize performance and energy savings. Additionally, a good VFD should offer features such as over-voltage protection, fault detection, and user-friendly programming to cater to the complexities of diverse motor applications. Overall, the significance of VFD controllers in enhancing the efficiency and longevity of motor systems cannot be overstated.

Key Factors to Consider When Choosing a VFD Controller

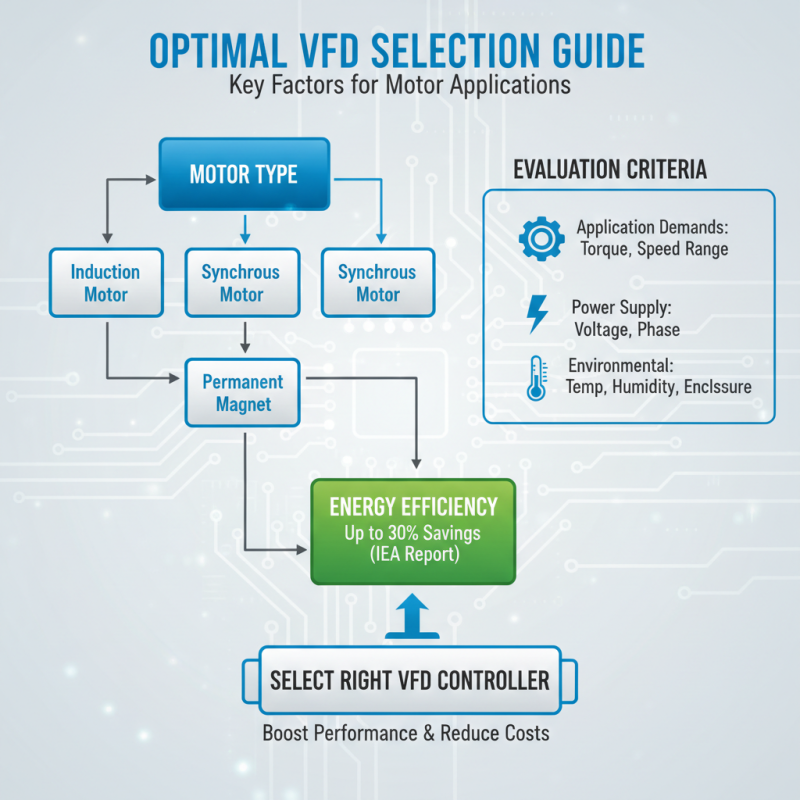

When selecting the right Variable Frequency Drive (VFD) controller for motor applications, several key factors must be thoroughly evaluated to ensure optimal performance and efficiency. One of the primary considerations is the type of motor involved, whether it’s an induction, synchronous, or permanent magnet motor. Industry reports, such as those from the International Energy Agency (IEA), indicate that efficient motor operation can reduce energy consumption by up to 30%, highlighting the importance of matching the VFD to the specific motor characteristics and application demands.

Another crucial factor is the operational environment. VFDs can be affected by temperature, humidity, and electromagnetic interference; therefore, understanding the conditions in which the motor will operate is vital. According to a recent study by the U.S. Department of Energy, improper VFD application can lead to a 15% decrease in energy efficiency, emphasizing the necessity for environmental compatibility in VFD selection. Additionally, features such as braking methods, communication protocols, and user interface also play significant roles in enhancing operational reliability and maintenance efficiency. By considering these variables, users can maximize productivity and minimize costs in their motor applications.

Types of VFD Controllers Available in the Market Today

When selecting a Variable Frequency Drive (VFD) controller for motor applications, it's essential to understand the various types available in the market today. There are three primary categories: Volts per Hertz (V/F) Control, Vector Control, and Direct Torque Control (DTC). V/F controllers are the most basic type, ideal for simple applications requiring constant torque. According to the NEMA (National Electrical Manufacturers Association), around 40% of industrial motor applications utilize V/F control due to its cost-effectiveness and straightforward implementation.

On the other hand, Vector Control drives provide improved performance by maintaining precise control of motor speed and torque, even under varying loads. This technology allows for better efficiency and responsiveness, making it suitable for applications like servo drives and CNC machines. Industry reports suggest that the adoption of vector control systems is expected to grow by over 25% by 2025, driven by the demand for higher efficiency in complex applications.

Lastly, Direct Torque Control (DTC) is favored in high-performance applications such as escalators and high-speed spindles. DTC provides rapid response times and superior torque control, which is increasingly critical in modern automation processes. Reports indicate that while DTC represents a smaller segment of the VFD market, its penetration is expected to rise significantly, with advanced applications leading the charge towards its broader acceptance in the coming years.

2025 How to Choose the Right VFD Controller for Your Motor Applications

| Type of VFD Controller | Key Features | Best Applications | Price Range |

|---|---|---|---|

| Scalar VFD | Simple control, Cost-effective | Pumps, Fans | $200 - $800 |

| Vector Control VFD | High torque performance, Precision control | Cranes, Conveyors | $500 - $1500 |

| Servo Drives | Feedback control, High acceleration | Robotics, CNC Machines | $1000 - $3000 |

| PWM VFD | Efficient energy usage, Less harmonic distortion | HVAC systems, Industrial fans | $300 - $1200 |

| Multi-Level VFD | Lower losses, Better performance | Large motors, Renewable energy systems | $1500 - $5000 |

Assessing Motor Compatibility with VFD Controller Selection

When selecting a Variable Frequency Drive (VFD) controller for motor applications, ensuring compatibility with the specific motor type is crucial for optimizing performance. Motors, whether AC or DC, come with distinct operational characteristics and requirements that must align with the capabilities of the chosen VFD. For instance, AC motors typically require a VFD that can manage varying frequency outputs, while DC motors may rely on controllers designed to handle constant voltage. Understanding the motor's specifications, such as voltage ratings, current capacity, and the desired speed range, is fundamental in guiding the selection process.

Moreover, assessing the application's demands plays a significant role in the compatibility assessment. Factors like load characteristics and operational environment should influence the choice of a VFD. For example, if the motor is intended for high-torque applications, the controller must be capable of delivering the necessary power without compromising efficiency. Additionally, safety features such as overcurrent protection and thermal overload safeguards should align with motor needs to prevent potential damage. Thus, a comprehensive evaluation of both the motor compatibility and application requirements ensures an informed decision, leading to enhanced operational reliability and longevity of the system.

This chart illustrates the compatibility scores of various motor types with VFD controllers. A higher score indicates better compatibility, which is essential when selecting the appropriate VFD controller for specific motor applications.

Common Applications and Benefits of Using VFD Controllers

Variable Frequency Drives (VFDs) have become indispensable in a variety of motor applications due to their ability to regulate speed and torque, which directly enhances energy efficiency. Common applications include HVAC systems, pumps, and conveyor systems, where precise control over motor speed is crucial for operational efficiency. By adjusting the frequency and voltage supplied to the motor, VFDs allow these systems to consume only the energy necessary for their current operation rather than running at full capacity continuously. This capability not only reduces energy costs but also minimizes wear and tear on equipment, extending its lifespan significantly.

In addition to energy savings, VFD controllers provide improved process control and flexibility. For instance, in manufacturing environments, the ability to adjust motor speed can lead to higher production rates and better product quality. Moreover, VFDs can include features such as soft-start capabilities, which reduce mechanical stress on the drive system during startup, thereby enhancing reliability. The adaptability of VFDs makes them suitable for various industry sectors, from food processing to pulp and paper, showcasing their broad benefits and effectiveness.

Related Posts

-

10 Best VFD Controllers You Need to Know for Optimal Performance

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

-

Understanding the Benefits of Variable Speed Drives in Modern Industry

-

Exploring the Impact of ATO Single Phase VFD on Energy Efficiency and Cost Savings in Modern Applications

-

Understanding the Importance of EMI Filters for VFD Applications in Modern Industry

-

A Comprehensive Comparison of 220V VFD Single Phase Drives for Optimal Motor Performance