Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Challenges When Choosing the Best Emi Filter for Vfd Applications

In the world of industrial automation, the integration of Variable Frequency Drives (VFDs) has become increasingly prevalent, yet the rise in their usage highlights a critical challenge: electromagnetic interference (EMI). A recent survey conducted by the International Electrotechnical Commission (IEC) revealed that over 60% of manufacturers report operational disruptions linked to EMI-related issues. Selecting the right EMI filter for VFD applications is essential not only for maintaining system integrity but also for ensuring compliance with stringent electromagnetic compatibility (EMC) standards. As VFDs drive greater energy efficiency and control, the necessity for effective EMI filtering becomes paramount in safeguarding both equipment and operational reliability. Addressing these challenges requires a comprehensive understanding of the myriad factors influencing performance and cost, making the selection of the most suitable EMI filter for VFD an essential yet complex task for engineers and system designers.

Understanding EMI Filters: Key Considerations for VFD Applications

When selecting the best EMI filter for Variable Frequency Drive (VFD) applications, understanding the unique requirements of your system is crucial. EMI filters play a vital role in mitigating electromagnetic interference, which can lead to equipment malfunctions, including bearing failures. By absorbing EMI at the source, advanced solutions can significantly enhance the reliability and efficiency of VFDs.

Tip 1: It's essential to assess the operating environment and the specific frequencies involved in your application. This knowledge helps in choosing a filter that effectively addresses the predominant noise issues, thereby protecting your components from potential damage.

Tip 2: Consider the installation and integration of EMI filters within your VFD system. An improperly installed filter can undermine its effectiveness, so ensure that mounting and connections are secure and in alignment with the manufacturer's guidelines.

Tip 3: Regular testing and maintenance of EMI filters can prevent unforeseen problems. Implementing a routine check-up schedule can help identify wear or performance degradation, enabling proactive measures to ensure longevity and optimal functionality of your VFD systems.

The Impact of VFDs on Electromagnetic Interference and Signal Integrity

In the realm of Variable Frequency Drives (VFDs), the management of electromagnetic interference (EMI) becomes paramount. VFDs operate by modulating the power supply to motors, which inadvertently generates electromagnetic noise that can compromise signal integrity in surrounding electronic devices. This interference can lead to erratic behavior in sensitive equipment, highlighting the need for effective EMI filtering solutions tailored for VFD applications.

Recent advancements in EMI performance, such as the introduction of integrated isolation power solutions, demonstrate a proactive approach to these challenges. With patented EMI enhancement technologies, these new devices can significantly optimize the noise performance at the component level, allowing for compliance with stringent testing standards like CISPR32 Class B. This not only ensures the reliability of VFD systems but also mitigates the adverse effects of electromagnetic disturbances on signal integrity, which is critical in today’s interconnected electronic landscape.

Selecting the Right EMI Filter: Types and Features to Consider

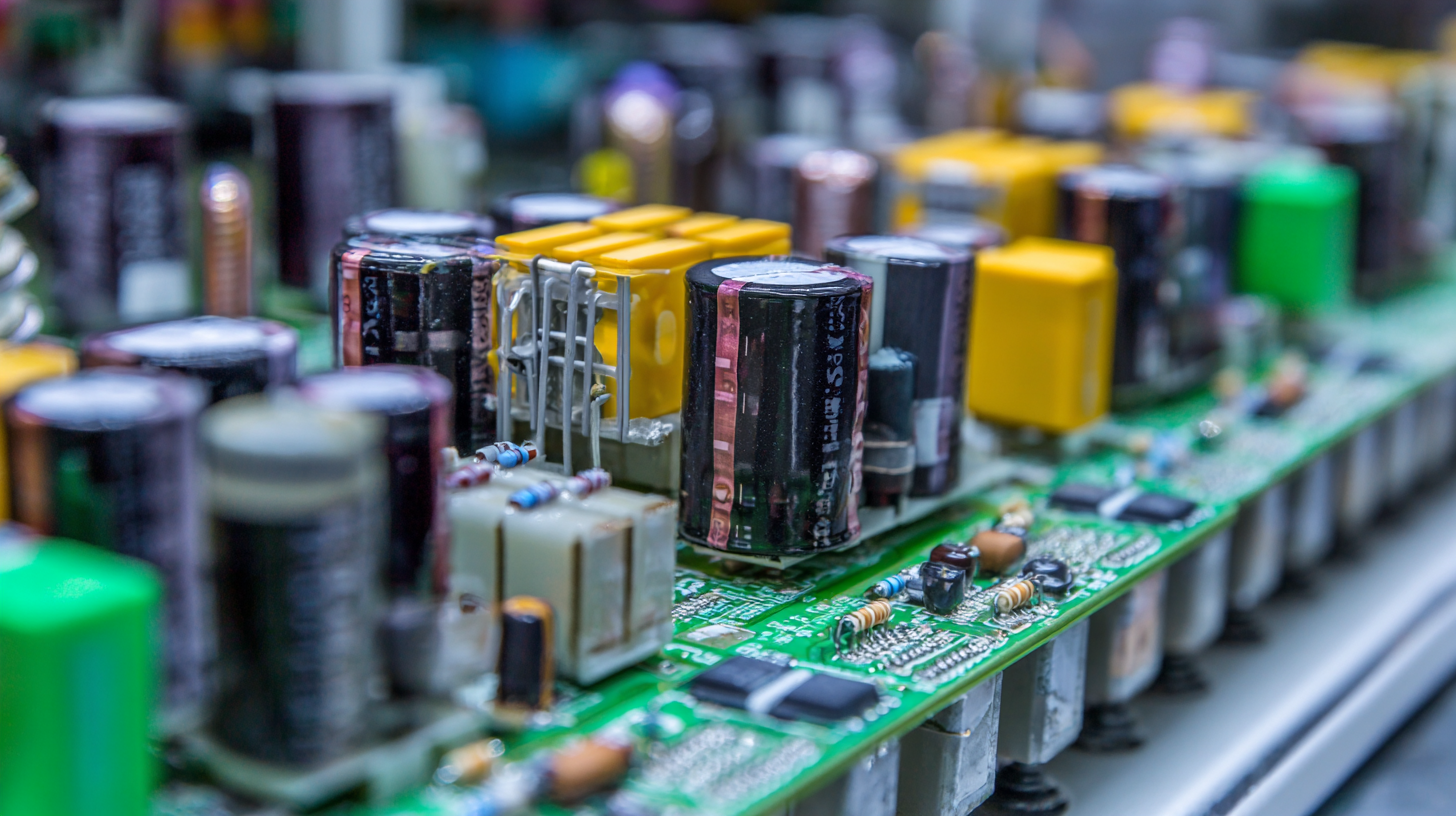

When selecting the right EMI filter for Variable Frequency Drive (VFD) applications, it's crucial to understand the various types and features available. EMI filters can be categorized into passive and active types, with passive filters being the most common due to their simplicity and effectiveness in reducing electromagnetic interference. Passive filters typically utilize capacitors and inductors to suppress high-frequency noise, whereas active filters employ complex circuitry to dynamically counteract EMI. Knowing which type is best suited for your specific VFD application can help in achieving optimal performance and compliance with regulatory standards.

Another key aspect to consider is the filter’s specifications, including its frequency range, insertion loss, and voltage rating. Make sure to select a filter that can effectively attenuate the specific frequencies that may cause interference in your electrical system. Furthermore, consider the environment where the filter will be installed; factors such as temperature, humidity, and space constraints can influence the filter's performance and durability. By carefully evaluating these types and features, you can ensure that you choose the most efficient EMI filter for your VFD application, thereby enhancing system reliability and efficiency.

Challenges When Choosing the Best EMI Filter for VFD Applications

| Type of EMI Filter | Key Features | Typical Applications | Challenges |

|---|---|---|---|

| Single-Phase EMI Filters | Compact design, good attenuation performance | Residential, light industrial motors | Limited current handling capacity |

| Three-Phase EMI Filters | High performance, low leakage, earth noise reduction | Heavy industrial motors, pumps | Complex design, higher cost |

| Line Reactors | Voltage drop mitigation, harmonic reduction | Induction motors, drives | Physical size, weight concerns |

| Common Mode Chokes | Effective against common mode noise | Precision equipment, medical devices | Limited to specific frequency ranges |

| Power Line Filters | Integrated solution for broadband noise | Industrial machinery, automation systems | Can affect power factor |

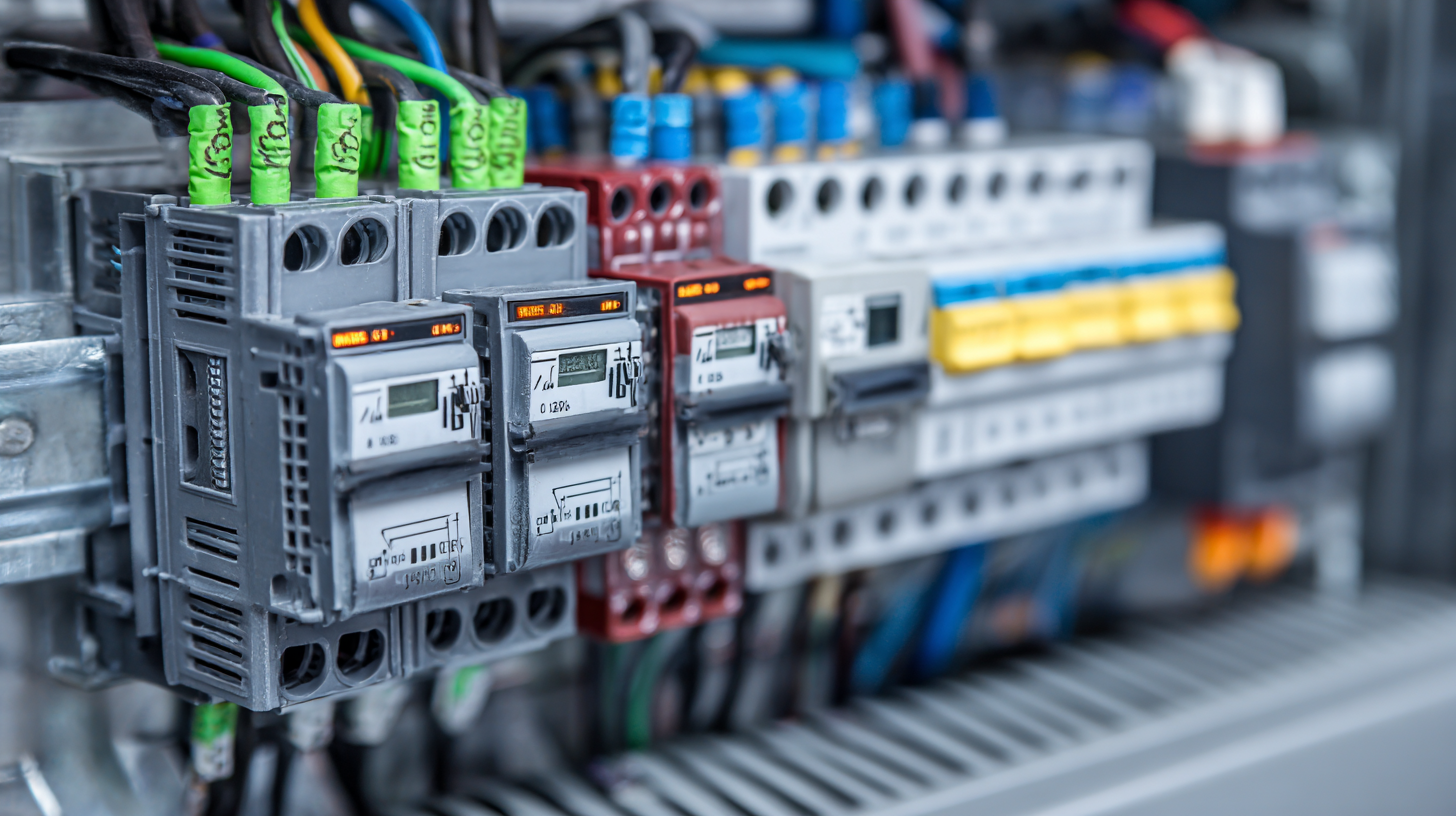

Common Challenges in EMI Filter Implementation for VFD Systems

When implementing EMI filters in Variable Frequency Drive (VFD) systems, engineers often encounter several challenges that can complicate the design and deployment processes. One major issue is the need to balance filtering effectiveness with system efficiency. According to a report by the International Electrotechnical Commission (IEC), improperly designed EMI filters can lead to significant losses in power efficiency—often more than 5% for high-frequency electronic noise. This inefficiency impacts the overall performance of the VFD, necessitating careful consideration and design optimization.

Another common challenge is the compatibility of EMI filters with existing equipment. Many VFD systems operate in environments where electromagnetic interference (EMI) is a critical concern, yet the filters themselves can introduce new harmonics. A study by the IEEE showed that nearly 40% of VFD installations face issues with harmonics due to poorly chosen or implemented EMI filters. Furthermore, selecting filters that comply with industry standards, such as IEC 61000-3-2 for harmonic emissions, adds another layer of complexity, as it requires comprehensive knowledge of both regulatory frameworks and the specific operational parameters of the VFD system. This interplay between compliance and performance underscores the necessity for thorough evaluation during the EMI filter selection process.

Future Trends in EMI Filter Technology for Enhanced VFD Performance

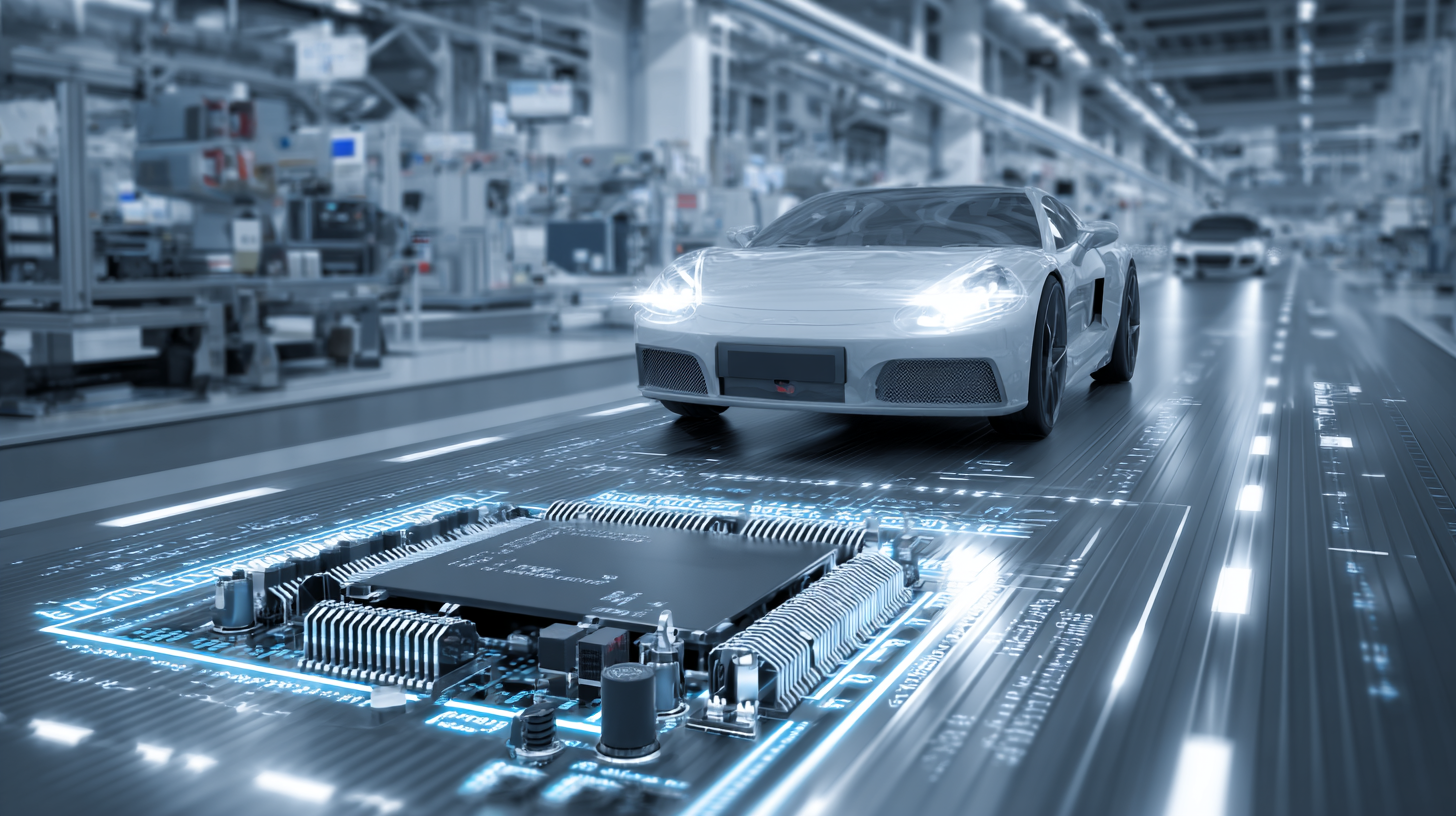

As the industry moves towards enhanced efficiency and sustainability, the demands on EMI filters in VFD applications are evolving significantly. The latest trends in EMI filter technology reflect a broader push for improved performance in various sectors, particularly with the rise of advanced electric motors and variable frequency drives (VFDs). With innovations like high-efficiency medium voltage motors, it is crucial to optimize EMI filters to mitigate electromagnetic interference, ensuring smoother operation and better performance of these intricate systems.

In particular, the electrification of industrial hydraulics highlights the need for sophisticated EMI filter solutions, as traditional hydraulic systems transition into quieter, more energy-efficient counterparts. This transition not only reduces noise but also necessitates the development of filters that can handle the unique challenges posed by new technologies. As VFDs become more prevalent, integrating permanent magnet motors and advanced control systems will demand cutting-edge EMI technology to enhance reliability and efficiency, making it essential for manufacturers to stay ahead of these trends.