Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

10 Best VFD Controllers You Need to Know for Optimal Performance

In the realm of industrial automation and energy efficiency, the importance of Variable Frequency Drive (VFD) controllers has reached unprecedented levels. According to a report by Allied Market Research, the global VFD market is projected to reach $25 billion by 2027, driven by the increasing emphasis on energy conservation and automation in manufacturing processes. These devices are essential for controlling the speed and torque of electric motors, thereby enhancing operational efficiency and reducing energy consumption.

As industries strive for optimal performance and sustainability, understanding the best VFD controllers available in the market becomes crucial. In this ultimate guide, we will explore the 10 best VFD controllers that not only promise advanced features and reliability but also contribute significantly to improved productivity and reduced operational costs.

Top 10 VFD Controllers That Maximize Energy Efficiency

When it comes to enhancing energy efficiency in industrial applications, Variable Frequency Drives (VFDs) play a crucial role. According to the U.S. Department of Energy, VFDs can improve motor efficiency by 20-50% when used to control AC motors, thereby significantly reducing energy consumption and operational costs. These devices adjust the motor speed to match the specific load requirements, preventing unnecessary energy expenditure that can occur with traditional fixed-speed motors.

Moreover, a recent report from the International Energy Agency (IEA) highlights that integrating advanced VFD controllers can lead to energy savings of up to 30% in HVAC systems alone. This not only translates to reduced energy bills but also contributes to lower greenhouse gas emissions, aligning with global sustainability goals. As businesses increasingly recognize the importance of energy management, investing in VFD technology becomes imperative for maximizing both performance and environmental responsibility.

Energy Efficiency of Top 10 VFD Controllers

This chart represents the energy efficiency measured in percentage (%) of the top 10 VFD controllers. Higher percentages indicate better energy efficiency, which is crucial for optimal performance in various applications.

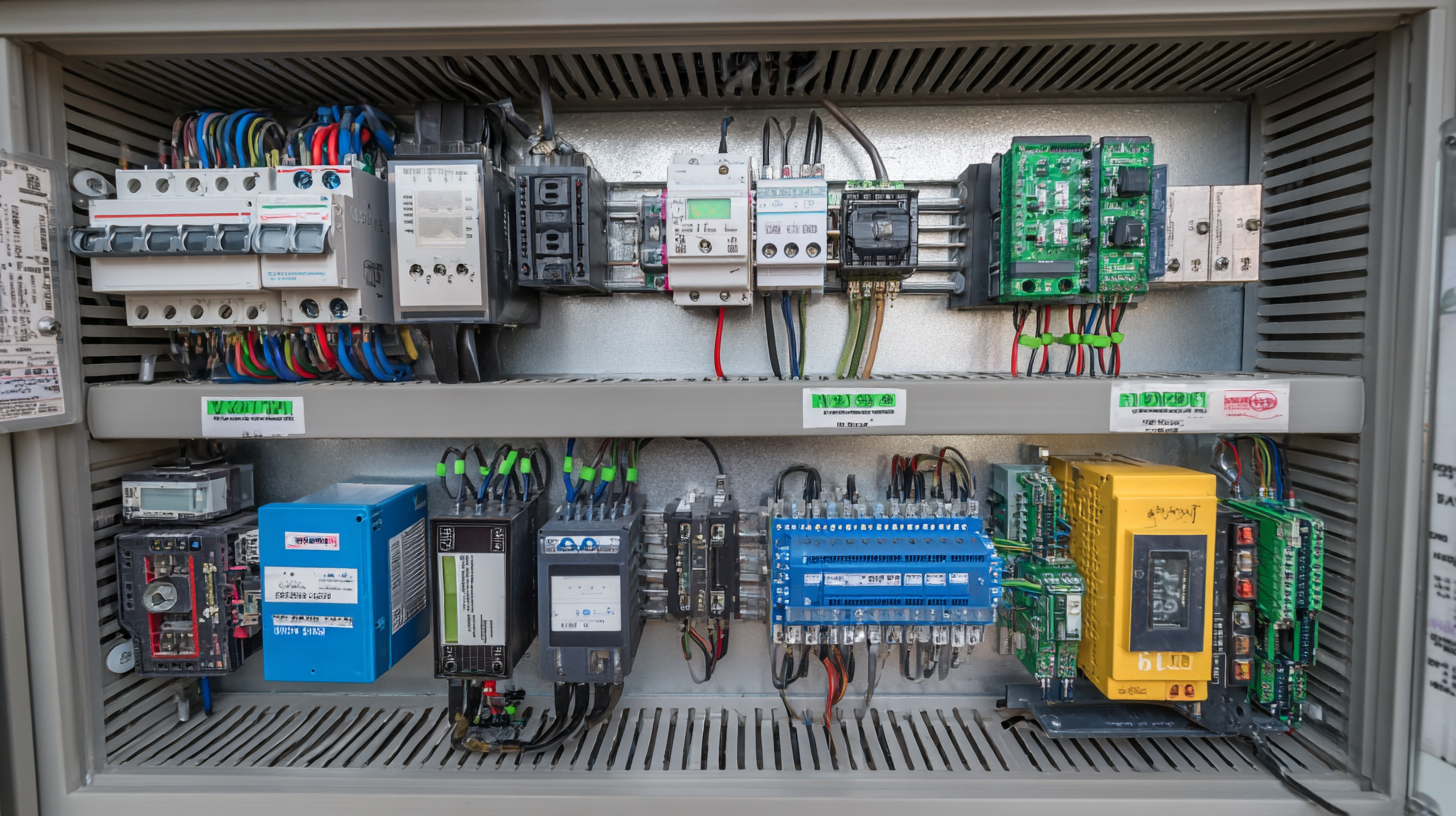

Key Features of VFD Controllers That Enhance Industrial Performance

When selecting Variable Frequency Drive (VFD) controllers, it's crucial to consider key features that significantly enhance industrial performance. One of the most important characteristics is the motor control method, which can drastically influence the efficiency of operations. Sensorless vector control allows for precise speed regulation and torque management, resulting in smoother operation and better energy savings. Additionally, built-in safety features such as overvoltage protection and thermal overload prevention ensure the longevity of both the drive and the connected motors, minimizing downtime and maintenance costs.

Another critical feature is the communication capability of VFD controllers. Integrated communication protocols such as Modbus, CANopen, or Ethernet/IP enable seamless integration with other automation systems. This connectivity allows for real-time monitoring and adjustments, contributing to improved system responsiveness and control. Furthermore, user-friendly interfaces with advanced feedback options empower operators to optimize performance through quick adjustments and access to critical data. By focusing on these essential features, industries can ensure that their VFD controllers not only meet performance requirements but also enhance overall operational efficiency.

5 Reasons to Upgrade to Advanced VFD Controllers for Your Machinery

Upgrading to advanced Variable Frequency Drive (VFD) controllers is a strategic move that can significantly enhance the operational efficiency of machinery. According to a recent report from the International Energy Agency (IEA), industrial sectors that adopt improved VFD technology witness energy savings ranging from 20% to 50%. This not only reduces operational costs but also contributes to sustainability efforts by lowering carbon emissions. With energy around 25% of the total operational costs for many manufacturers, the return on investment for upgrading VFDs becomes overwhelmingly justifiable.

Moreover, advanced VFD controllers come with enhanced features such as better motor control, diagnostics, and communication capabilities. The Market Research Future report indicates that robust VFD technologies can extend equipment life by up to 30% due to their superior ability to manage torque and speed fluctuations. Additionally, these controllers facilitate predictive maintenance by providing real-time data analytics, which can prevent unexpected downtimes that typically cost production facilities thousands of dollars in lost productivity. Adopting advanced VFDs can therefore be seen not just as an upgrade but as a crucial step towards achieving both economic and operational excellence in manufacturing processes.

The Impact of VFD Controllers on Equipment Longevity and Maintenance Costs

Variable Frequency Drives (VFD) play a crucial role in enhancing the longevity and efficiency of industrial equipment. By controlling the speed and torque of electric motors, VFDs reduce mechanical stress, which directly translates to a longer lifespan for machinery. In the context of today's rapidly evolving market, the growing emphasis on preventive maintenance highlights the importance of integrating VFD controllers. As industries expand and adopt automated systems, incorporating VFDs leads to significant reductions in energy consumption and operational costs, ultimately impacting maintenance strategy positively.

The recent growth trends in sectors, such as CNC manufacturing and public utility pumps, further underline the relevance of VFD technology. As these markets are projected to experience significant growth in the coming years, the demand for reliable and efficient control systems will increase. VFDs not only optimize performance but also minimize maintenance expenses by preventing wear and tear on components. Such advancements ensure that organizations can maintain their competitive edge while achieving sustainability objectives. Consequently, investing in high-quality VFD controllers can lead to remarkable improvements in both equipment lifespan and cost-efficiency across various industries.

10 Best VFD Controllers You Need to Know for Optimal Performance

| Model | Power Rating (kW) | Voltage (V) | Control Type | Efficiency (%) | Expected Lifespan (Years) | Maintenance Cost (Annual) |

|---|---|---|---|---|---|---|

| Model A | 5 | 230 | V/f Control | 95 | 10 | $200 |

| Model B | 7.5 | 400 | Vector Control | 97 | 12 | $250 |

| Model C | 10 | 480 | Flux Vector | 95 | 15 | $300 |

| Model D | 15 | 600 | Servo Control | 98 | 20 | $350 |

| Model E | 20 | 690 | Direct Torque Control | 96 | 25 | $400 |

How to Choose the Right VFD Controller for Your Specific Application Needs

Choosing the right Variable Frequency Drive (VFD) controller for your specific application needs is crucial for achieving optimal performance. First, it's essential to understand the requirements of your motor and the overall system. Consider factors such as the type of load, required torque, and speed range. For instance, applications involving centrifugal pumps may need a different approach compared to those for conveyor belts. Evaluating these parameters will help narrow down your options.

Next, think about the environmental conditions and the operational setting where the VFD will be deployed. Factors such as temperature ranges, humidity levels, and the presence of dust or chemicals can significantly impact the choice of VFD. Additionally, ease of integration with existing systems and compatibility with control interfaces should also be assessed. Prioritize controllers that offer advanced features such as energy-saving modes, user-friendly programming, and maintenance diagnostics, as these can enhance performance and prolong the lifespan of your equipment. By considering these critical aspects, you can select a VFD controller that aligns perfectly with your application, ensuring efficiency and reliability in your operations.