Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Best 220V VFD Single Phase Motor Drives for Home Use?

In the world of home automation, many seek the best 220V VFD single phase motor drives. These drives enhance efficiency and control. They also turn simple tasks into seamless operations. Choosing the right model can seem daunting.

Understanding the features of each drive is crucial. Some may offer advanced control settings, while others could lack essential functionalities. For instance, not every unit delivers smooth performance under load. Customers often report inconsistent results. These reflections guide potential buyers in their decisions.

Selecting a 220V VFD single phase motor drive requires careful consideration. Users must balance price, reliability, and performance. Each choice impacts daily tasks. A poorly chosen drive can lead to frustration. It's essential to look for products that meet specific needs while also learning from existing shortcomings.

Understanding Variable Frequency Drives (VFD) and Their Benefits

Variable Frequency Drives (VFDs) are essential for controlling motor speed. They adjust the power supply frequency. This feature enhances energy efficiency. More efficient motors save money on your electricity bill. It’s a straightforward way to improve your home's energy use.

Using a VFD for a single-phase motor allows for better control of speed and torque. This capability can be beneficial for various home applications. For example, in pumps and fans, varying the speed can lead to significant energy savings. However, selecting the right VFD can be challenging. Not all VFDs suit every application perfectly. Compatibility with your motor is crucial.

Many users overlook installation complexity. Proper setup may require technical knowledge. Misconfiguration can lead to performance issues. It's important to consult manuals and guidelines. Gain a clear understanding of your needs before purchasing. Take your time to research and consider all options.

Best 220V VFD Single Phase Motor Drives for Home Use

| Model | Power Rating (HP) | Input Voltage (V) | Output Frequency (Hz) | Control Method | Features |

|---|---|---|---|---|---|

| Model A | 1 HP | 220V | 0-60 Hz | V/f Control | Overload Protection, PID Control |

| Model B | 2 HP | 220V | 0-50 Hz | Sensorless Vector Control | Extensive Protection Features |

| Model C | 1.5 HP | 220V | 0-60 Hz | Open Loop Control | Compact Design, Easy Setup |

| Model D | 3 HP | 220V | 0-60 Hz | Vector Control | Built-in Brake Control, User-friendly Interface |

Key Features to Look for in 220V Single Phase VFDs

When looking for a 220V single-phase Variable Frequency Drive (VFD) for home use, certain features stand out. The first key aspect is the power range. Ensure it matches your motor specifications. A drive meant for small machines often lacks the capacity. Conversely, oversized units can be inefficient.

Another important feature is the control options. The best VFDs come with multiple control modes, such as keypad control or external potentiometer options. This versatility allows you to adapt the drive for different applications, but simplicity matters too. A complicated interface can create confusion.

Consider the starting and stopping features as well. Soft start and stop capabilities help prevent motor wear and tear. Regular abrupt starts can lead to motor damage over time, so this feature is almost essential. Lastly, look for built-in protections, such as over-voltage and over-current safeguards. Having these will add a layer of reliability. However, remember that these features can complicate the setup. Assess your needs carefully before making a choice.

Top Recommendations for Home Use VFDs on the Market

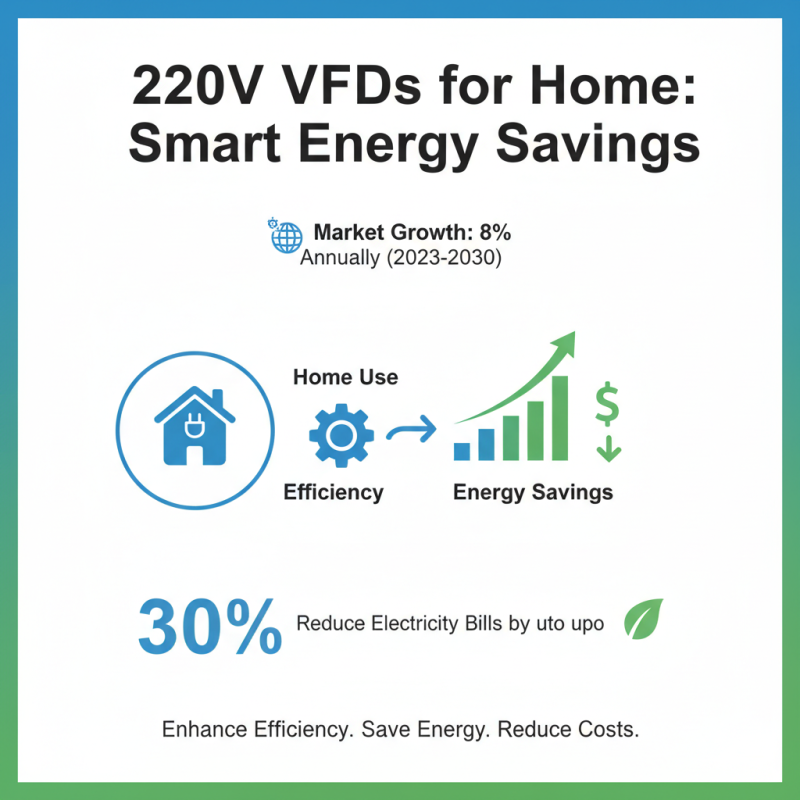

When choosing a 220V VFD for home use, various options exist. A report by Research and Markets indicates a projected growth rate of 8% annually in the VFD market. These drives enhance efficiency and save energy, which is vital for homeowners. The right VFD can reduce electricity consumption by up to 30%, significantly benefiting your energy bills.

Not all VFDs are suitable for every application. For example, some models may only be compatible with specific single-phase motors. Compatibility issues can lead to inefficient performance or damage. The average lifespan of a VFD ranges between 5 to 15 years, but factors like installation quality and maintenance can affect durability. Investing time in research could prevent unnecessary costs down the line.

Many users report struggling with installation. While some VFDs come with easy setup instructions, others do not. Therefore, understanding your system is crucial. Online forums can be a valuable resource for troubleshooting common issues. Picking the right model might involve trial and error, and it’s essential to track how well a device performs in your unique environment.

Installation and Setup Tips for Home VFD Systems

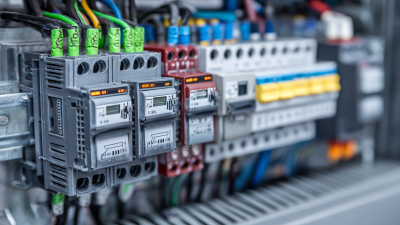

When setting up a VFD (Variable Frequency Drive) for home use, proper installation is crucial. Start by ensuring a safe location for the VFD that is dry and well-ventilated. A clean environment can prevent overheating. Prepare the wiring according to the specifications, but remember that cutting corners here can lead to issues later. Double-check all connections before powering up.

Next, configure the VFD settings to match your motor's specifications. This often involves setting parameters like voltage, frequency, and current limits. Take the time to read the manual; skipping details can lead to errors that are hard to trace. It can be frustrating, but clarity in settings leads to better performance. If you experience unexpected behavior, revisiting these settings is wise.

During the initial test runs, keep an eye on the VFD’s performance. Look for unusual noises or vibrations. These could indicate misalignment or mounting problems. Don’t hesitate to make adjustments based on your observations. A little patience will ensure the system operates smoothly. Remember, learning from mistakes is a part of the setup process. Embrace it.

Maintenance and Troubleshooting for Your VFD Motor Drive

When using a VFD motor drive, proper maintenance is critical. Regular checks on the connections can prevent unexpected failures. Look for loose wires or corrosion. It's essential to monitor the temperature of the drive. Overheating can lead to serious damage, and this is often a sign of underlying issues.

Troubleshooting is part of the process. If the motor is not functioning, check the settings first. Sometimes, it could be a simple programming error. Make sure you read the manual carefully. Understand the parameters that change motor behavior. This understanding can save you from a lot of headaches.

Listening to the motor is equally important. Unusual noises may indicate mechanical problems. A grinding sound can be a warning sign. Addressing these issues early on can significantly extend the lifespan of the motor drive. Regularly servicing your equipment is not just a good practice; it's necessary.

Related Posts

-

Discover How China is Revolutionizing Global Markets with Best 220v VFD Single Phase Solutions

-

Discover High-Quality 220V VFD Single Phase Solutions from Leading Chinese Manufacturers

-

How to Choose the Right 220V VFD Single Phase for Your Motor Applications

-

2025 How to Choose the Right VFD Controller for Your Motor Applications

-

Understanding the Importance of EMI Filters for VFD Applications in Modern Industry

-

Challenges When Choosing the Best Emi Filter for Vfd Applications