Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Understanding the Benefits of Variable Speed Drives in Modern Industry

In the contemporary landscape of modern industry, the adoption of technology plays a pivotal role in enhancing operational efficiency and sustainability. One such advancement is the variable speed drive (VSD), which has become a cornerstone in optimizing motor performance across various sectors. According to a report by the International Energy Agency, implementing variable speed drives can lead to energy savings of up to 50% in specific applications, fundamentally transforming how industries approach energy consumption and cost management.

Experts like Dr. Emily Wong, a leading authority in industrial automation, emphasize the critical importance of VSD technology, stating, "Variable speed drives not only reduce energy usage but also extend the lifespan of equipment, making them an investment with dual benefits." As industries increasingly prioritize sustainability and efficiency, the implementation of VSDs stands out as a strategic decision that aligns with broader goals of operational excellence and environmental stewardship. This introduction lays the groundwork for an in-depth exploration of the benefits and applications of variable speed drives in various industrial contexts.

Key Advantages of Variable Speed Drives for Energy Efficiency

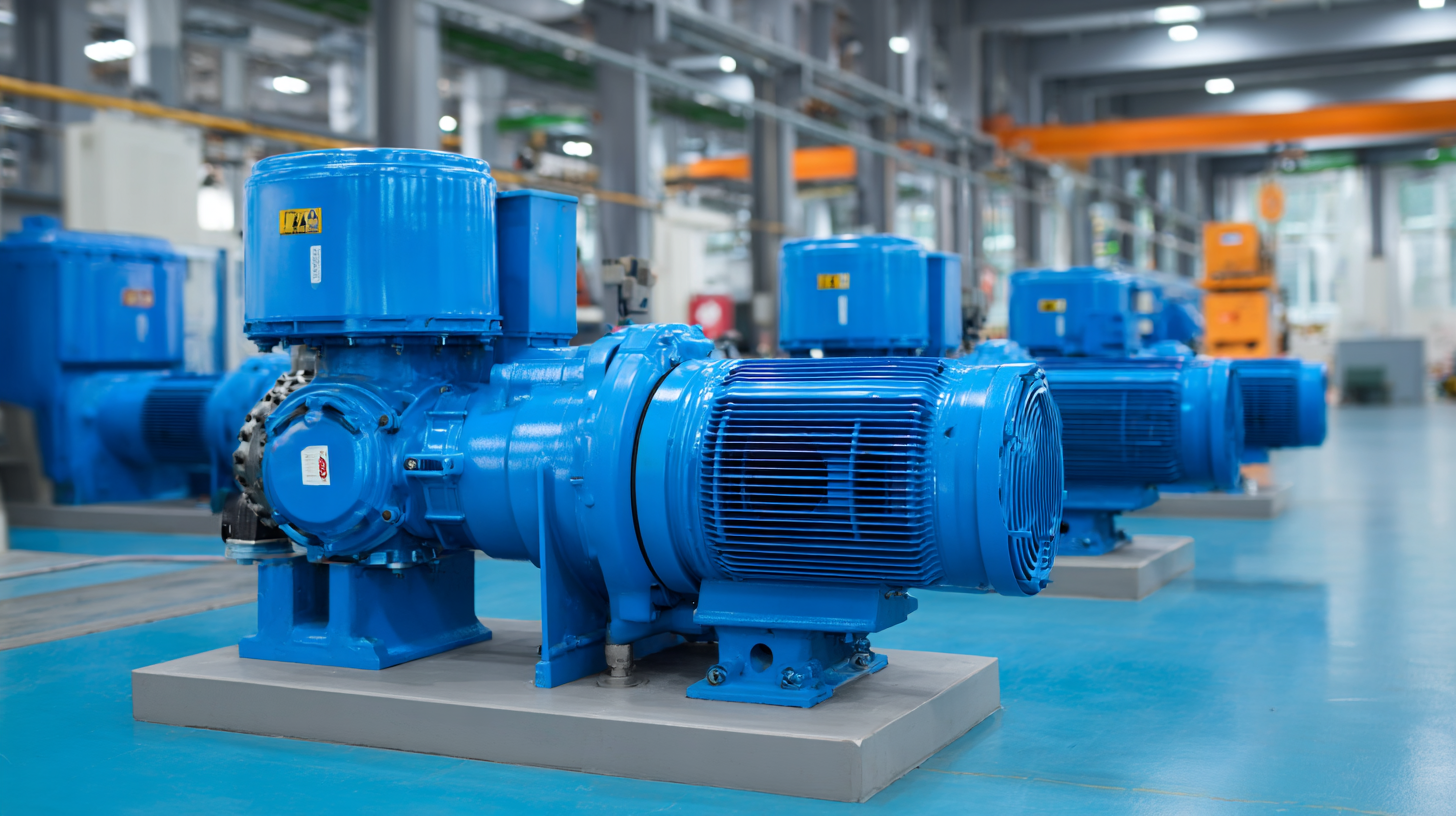

Variable speed drives (VSDs) are becoming increasingly essential in modern industry due to their significant contributions to energy efficiency. By allowing motors to adjust their speed according to real-time operational needs, VSDs can drastically reduce energy consumption. For instance, in applications like pump and fan control, where flow requirements can fluctuate, VSDs optimize energy usage by matching output to demand, ensuring that no excess energy is wasted.

Variable speed drives (VSDs) are becoming increasingly essential in modern industry due to their significant contributions to energy efficiency. By allowing motors to adjust their speed according to real-time operational needs, VSDs can drastically reduce energy consumption. For instance, in applications like pump and fan control, where flow requirements can fluctuate, VSDs optimize energy usage by matching output to demand, ensuring that no excess energy is wasted.

Tip: When implementing VSDs, consider conducting an energy audit to identify areas of improvement. This helps in selecting the right VSD for specific applications, maximizing energy savings.

Another key advantage of variable speed drives is their ability to improve system performance and lifespan. With reduced mechanical stress on components, VSDs enhance reliability and minimize wear. Smooth acceleration and deceleration reduce the risk of operational shocks that can lead to premature equipment failure, thereby extending the overall life of the machinery.

Tip: Regular maintenance checks on VSDs and connected equipment can further enhance performance. Maintain proper lubrication and inspect for wear and tear to ensure maximum efficiency and longevity.

Enhancing Equipment Longevity with Variable Speed Drives

Variable speed drives (VSDs) play a crucial role in modern industrial settings, particularly in enhancing the longevity of equipment. By allowing motors to operate at varying speeds, VSDs reduce the mechanical stress experienced during startup and operation. Traditional systems often subject machinery to abrupt changes in speed and torque, leading to premature wear and tear. In contrast, VSDs facilitate smoother transitions and optimize the operational parameters, significantly extending the lifespan of critical equipment.

Moreover, VSDs contribute to improved energy efficiency, which indirectly supports equipment maintenance. By matching the motor speed to the specific requirements of the process, these drives help minimize energy consumption and reduce heat generation. Lower operating temperatures not only enhance the efficiency of the machinery but also reduce the frequency of maintenance intervals. As a result, industries can achieve both economical benefits and increased reliability, ensuring that their equipment remains operational for longer periods. This synergy of performance and longevity solidifies the significance of variable speed drives in modern industrial applications.

Improving Process Control and Precision in Industrial Applications

Variable speed drives (VSDs) play a crucial role in enhancing process control and precision in modern industrial applications. By allowing the adjustment of motor speed to match the requirements of specific tasks, VSDs enable industries to achieve a higher level of operational efficiency. This adaptability not only reduces energy consumption but also minimizes wear and tear on machinery, leading to a longer lifespan and lower maintenance costs.

In applications such as conveyor systems, pumps, and fans, VSDs can finely tune performance to optimize production processes. For instance, in a manufacturing environment, a VSD can adjust the speed of a conveyor belt based on the flow of materials, ensuring a smooth operation that maintains product quality.

Additionally, the precise control offered by VSDs facilitates better compliance with process specifications, resulting in improved quality assurance and reduced variability in production outputs. As industries continue to strive for greater efficiency and reliability, the implementation of variable speed drives becomes increasingly vital for maintaining competitiveness and enhancing productivity.

Reducing Operational Costs through Optimized Performance

Variable speed drives (VSDs) play a crucial role in modern industrial applications by enabling machinery to operate at varying speeds according to real-time demand. This capability significantly enhances operational efficiency, which translates directly into reduced energy consumption. By adjusting motor speed to match the required load, VSDs prevent energy waste, allowing industries to decrease their overall operational costs. For example, in pumping systems, operating at variable speeds can lead to substantial energy savings, as unnecessary power draw during low-demand periods is minimized.

Moreover, the optimized performance at variable speeds leads to improved equipment lifespan and reduced maintenance costs. When machinery runs consistently at ideal speeds, wear and tear decreases, resulting in fewer mechanical failures and downtime. This not only enhances productivity but also enables companies to allocate resources more effectively. As industries continue to face pressure to improve their bottom lines, implementing VSD technology offers a clear pathway to sustainable cost reduction while maintaining high levels of operational performance.

Environmental Impact: Decreasing Carbon Footprint with Variable Speed Drives

Variable speed drives (VSDs) play a pivotal role in promoting sustainability within modern industries. By adjusting the speed of motors to match specific load requirements, these drives optimize energy consumption, significantly reducing the carbon footprint associated with industrial operations. This enhanced efficiency not only leads to cost savings but also contributes positively to environmental conservation, as lower energy usage translates to fewer greenhouse gas emissions.

Tips for implementing VSDs effectively include conducting an energy audit to identify opportunities for motor optimization and ensuring proper sizing of drives to maximize performance. Additionally, continuous monitoring of system performance can help detect inefficiencies and further minimize energy consumption over time.

Another benefit of VSDs is their capacity to extend the lifespan of equipment by reducing wear and tear. When motors operate at lower speeds, they encounter less mechanical stress, promoting longevity and reliability. To maximize these advantages, it is essential to integrate a proactive maintenance schedule and keep an inventory of spare parts to quickly address potential issues without disrupting productivity.

Related Posts

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive

-

What Are EMI Filters and How Do They Enhance Device Performance?

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

Challenges When Choosing the Best Emi Filter for Vfd Applications

-

Unlocking Energy Efficiency: How Motor Frequency Converters Transform Industrial Operations

-

Discover High-Quality 220V VFD Single Phase Solutions from Leading Chinese Manufacturers