Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Top 10 Benefits of Using an EMC Line Filter?

In today's rapidly advancing technological world, EMC line filters play a crucial role in ensuring electromagnetic compatibility. These devices help minimize interference in electronic equipment. Many industries rely on EMC line filters to improve performance and reliability.

The benefits of using an EMC line filter are significant. They protect sensitive devices from noise and spikes. This enhances device longevity and functionality. Moreover, they contribute to regulatory compliance. In some cases, the effectiveness of filters can vary based on the design. Users may encounter challenges in selecting the right filter for specific applications.

Exploring the benefits of EMC line filters reveals their importance in modern electronics. Understanding these advantages can lead to better decisions in system design. Users should reflect on their experiences with these filters for continuous improvement.

Advantages of EMC Line Filters in Electrical Systems

EMC line filters are crucial in modern electrical systems. They help reduce electromagnetic interference (EMI). This interference can disrupt the operation of sensitive electronic devices. According to a report by the International Electrotechnical Commission, about 30% of equipment failures are due to EMI. This statistic underscores the importance of using EMC filters.

Implementing EMC filters can enhance system reliability. They help maintain performance levels in noisy environments. For instance, studies show that systems with EMC filters experience 50% fewer disturbances. They also improve signal integrity. This is vital for communication devices that rely on clear signals.

However, some may overlook the necessity of these filters. A common issue is the added cost. In some cases, users feel that EMC filters add complexity without immediate benefits. Yet, investing in EMC line filters can be wise. When ignored, the cost of device failures and poor performance often exceeds initial savings.

Enhancing Equipment Performance Through EMC Line Filters

EMC line filters are vital for enhancing equipment performance. They effectively reduce electromagnetic interference (EMI), which can disrupt normal operations. By using these filters, equipment can communicate better, leading to fewer errors. This is critical for sensitive instruments in labs or industrial settings.

In practical terms, a line filter can improve the lifespan of electrical devices. It minimizes disturbances from power sources, ensuring clean power delivery. Additionally, the installation process can be tricky. If not done correctly, the benefits may not be fully realized. Filtering out noise should never be underestimated.

While many focus solely on performance, it's important to consider cost. Savings on repairs and downtime can outweigh initial expenses. However, selecting the right filter requires thought. A generic filter may not fit every application. Proper evaluation and testing should guide decisions for optimal results.

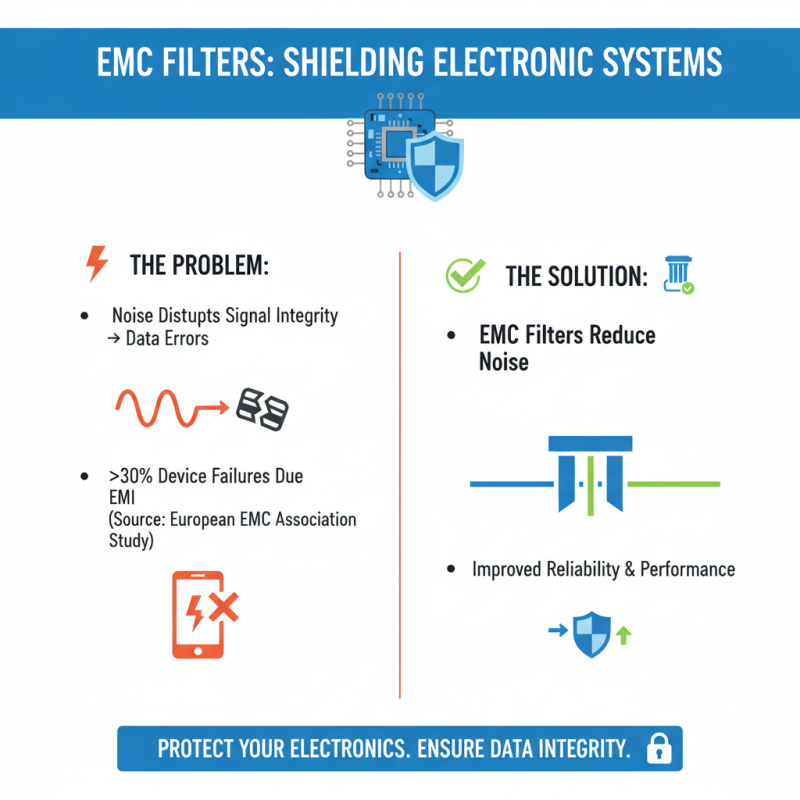

Noise Reduction and Signal Integrity Improvement with EMC Filters

EMC filters play a crucial role in reducing noise in electronic systems. Noise can disrupt signal integrity, leading to data errors. According to a study conducted by the European EMC Association, over 30% of electronic device failures are linked to electromagnetic interference. This figure highlights the importance of implementing effective EMC solutions.

When using EMC filters, users can significantly improve signal performance. Analyses have shown that adding a well-designed filter can improve signal-to-noise ratio by as much as 15 dB. This enhancement reduces the likelihood of interference causing data loss. In a world increasingly reliant on precise data transmission, even minimal improvements can have substantial impacts.

However, not all systems benefit equally from EMC filters. Some applications may see marginal returns. It's essential to consider specific needs rather than making blanket assumptions. A tailored approach to EMC filter selection and implementation often yields the best results. Careful analysis can reveal the right balance between cost and functionality, ensuring that investments are justified.

Protection Against Electromagnetic Interference (EMI)

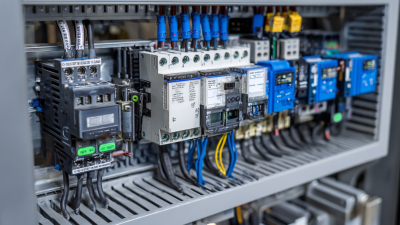

Electromagnetic Interference (EMI) is an unseen challenge in various industries. It can disrupt machinery, leading to costly downtime. According to a report by the International Electrotechnical Commission, EMI can cause a productivity loss of up to 20% in manufacturing plants. This interference can originate from many sources, including motors, frequency inverters, and even external devices.

Using an EMC line filter offers a robust solution. These filters work by attenuating unwanted noise from electrical signals. They help maintain the integrity of communication lines and power distribution systems. A study from the International Journal of Electronics indicates that proper filtering can reduce EMI by as much as 40%. This means that machines operate more reliably, and the risk of malfunction decreases significantly.

Yet, challenges remain. Not all filters are effective for every application. Choosing the wrong type can lead to incomplete protection. This can expose systems to interference, negating the benefits. Knowing the specific EMI characteristics of your environment is crucial. Moreover, regular testing of filters is often overlooked. Maintaining their effectiveness over time is essential to sustain optimal performance.

Top 10 Benefits of Using an EMC Line Filter

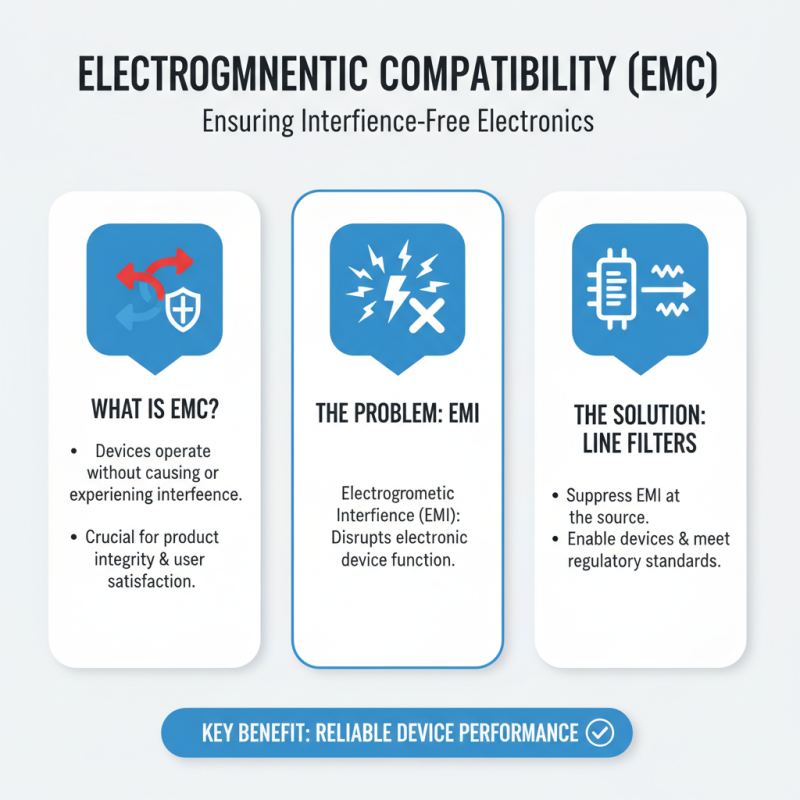

Compliance with EMC Regulations and Standards

Electromagnetic compatibility (EMC) is crucial for electronic devices. Compliance with EMC regulations ensures that your devices can operate without causing or experiencing interference. This is essential for maintaining product integrity and user satisfaction. Line filters play a key role in this compliance. They help suppress electromagnetic interference (EMI), allowing devices to function properly within existing standards.

By using an EMC line filter, you can avoid costly redesigns. It can be frustrating when a device fails to meet regulatory standards. This often requires time-consuming adjustments. An effective filter can simplify your engineering tasks. It helps protect sensitive components from voltage spikes and noise. However, selecting the right filter can be complex, and not all filters are created equal. This is an area where reflection and careful consideration are needed.

Incorporating line filters may enhance your product's performance. Yet, there can be trade-offs. Sometimes, filters are designed for specific applications. A filter that works for one product might not suit another. Testing and validation become necessary steps. Balancing compliance and performance involves introspection on design choices. It's a journey of constant improvement and adaptation.

Related Posts

-

5 Reasons Why Frequency Drive Controllers Are Essential for Global Procurement Success

-

How to Choose the Right 220V VFD Single Phase for Your Motor Applications

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

2025 How to Choose the Right VFD Controller for Your Motor Applications

-

A Comprehensive Comparison of 220V VFD Single Phase Drives for Optimal Motor Performance

-

7 Best Ways to Enhance Efficiency with Single Phase AC Drive