Connect with us today to learn more about our industrial automation solutions—and how to commission them for your application.

Top 10 Benefits of Using AC Motor VFD for Energy Efficiency and Performance

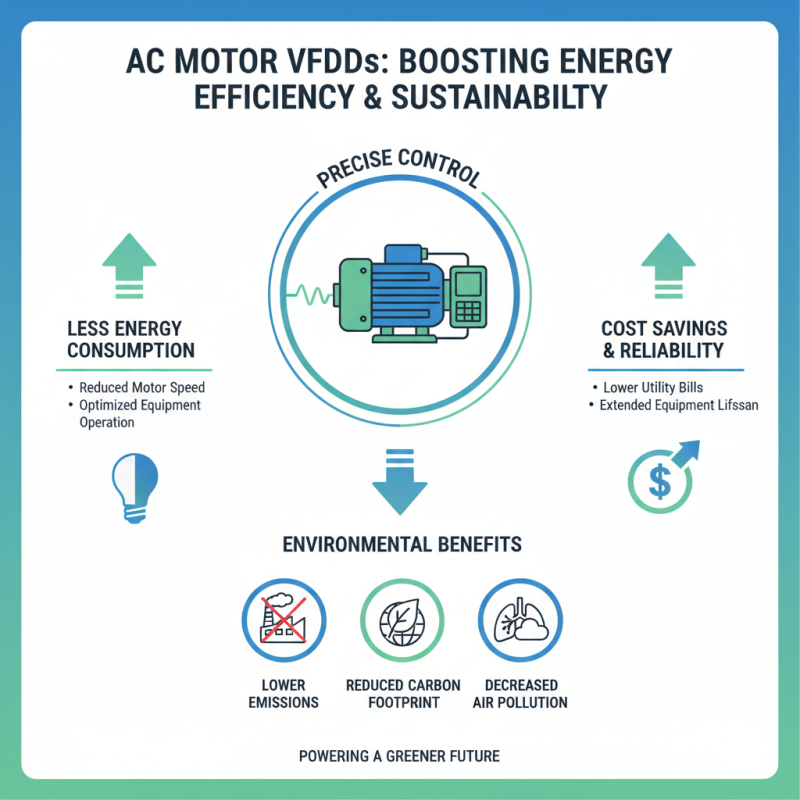

In today's rapidly evolving industrial landscape, energy efficiency and performance optimization have become paramount for businesses striving for sustainability and cost-effectiveness. One of the most effective solutions to achieve these goals is the utilization of AC motor VFD (Variable Frequency Drive) technology. By controlling the speed and torque of AC motors, VFDs not only enhance operational efficiency but also significantly reduce energy consumption. This makes them an invaluable tool for modern industries seeking to minimize their environmental impact while maximizing productivity.

The adoption of AC motor VFDs has witnessed a remarkable rise, as organizations increasingly recognize the multifaceted benefits that these systems offer. From improving process control to extending equipment lifespan, the advantages are both immediate and long-lasting. With the ability to adapt motor speed to actual load requirements, AC motor VFDs eliminate unnecessary energy waste and allow for precise operational adjustments that can lead to higher performance levels.

As we delve into the top ten benefits of using AC motor VFD technology, we will explore how these systems not only contribute to enhanced energy efficiency but also drive superior performance across various applications. Understanding these benefits can empower businesses to make informed decisions that align with both their operational goals and sustainability commitments.

Overview of AC Motors and Variable Frequency Drives (VFD)

AC motors are widely used in various industrial applications due to their robustness and efficiency. An AC motor converts electrical energy into mechanical energy through the interaction of magnetic fields, often providing a reliable solution for high-torque applications. According to a report by the U.S. Department of Energy, AC motors account for nearly 60% of the electrical energy consumed by the industrial sector, illustrating their significant impact on energy consumption and operational costs. Implementing energy-saving technologies in AC motors is crucial for boosting efficiency and reducing the environmental footprint.

Variable Frequency Drives (VFDs) play a pivotal role in enhancing the performance of AC motors by regulating their speed and torque. By adjusting the frequency and voltage supplied to the motor, VFDs enable precise control over motor operations, which can lead to substantial energy savings. A study published in the journal "Energy" noted that VFDs could reduce energy consumption by up to 50% in certain applications, such as pumps and fans, where speed adjustment is frequently required. This adaptability not only improves energy efficiency but also extends the lifespan of the equipment by decreasing wear and tear. Furthermore, as industry standards continue to evolve, the integration of VFD technology into AC motor systems is becoming increasingly essential for meeting stringent energy efficiency regulations and optimizing operational performance.

Top 10 Benefits of Using AC Motor VFD for Energy Efficiency and Performance

| Benefit | Description | Impact on Energy Efficiency |

|---|---|---|

| Energy Savings | Reduces energy consumption by adjusting motor speed to the required load. | Up to 60% energy savings possible. |

| Improved Motor Control | Provides precise control over motor speed and torque. | Enhances overall system performance. |

| Reduced Wear and Tear | Minimizes mechanical stress by avoiding sudden starts and stops. | Extends equipment lifespan. |

| Lower Maintenance Costs | Less frequent maintenance required due to reduced wear. | Cost savings on maintenance. |

| Enhanced System Flexibility | Easily adjusts to changing production requirements. | Increases productivity and efficiency. |

| Reduced Noise Levels | Operates at lower speeds when possible, reducing operational noise. | Contributes to a quieter working environment. |

| Improved Process Control | Allows for better synchronization of processes. | Optimizes overall system efficiency. |

| Power Factor Correction | Can improve the power factor, reducing demand charges. | Further reduces energy costs. |

| Integration with Automation Systems | Easily integrates with SCADA and PLCs for advanced monitoring. | Enhances overall operational visibility. |

| Sustainability Benefits | Reduces overall carbon footprint through energy efficiency. | Contributes to environmental sustainability goals. |

Understanding Energy Efficiency in Industrial Applications

Energy efficiency in industrial applications has become a critical focus as industries strive to minimize operational costs and environmental impact. One of the significant advancements contributing to this goal is the use of AC motor Variable Frequency Drives (VFDs). By allowing for precise control of motor speed and torque, VFDs not only enhance the overall performance of industrial equipment but also optimize energy consumption. When motors can operate at speeds that match the demand rather than running at a constant rate, there is a substantial reduction in wasted energy, leading to lower electricity bills and reduced carbon emissions.

Moreover, understanding energy efficiency extends beyond mere cost savings; it encompasses maintaining equipment reliability and extending the lifespan of machinery. VFDs can reduce wear on motors and other connected components by smoothing out the startup process and minimizing mechanical stress. This results in fewer maintenance requirements and downtime, further contributing to operational efficiency.

As industrial sectors increasingly prioritize sustainability, the integration of AC motor VFDs emerges as a practical solution that aligns economic viability with environmental responsibility, proving essential in today's energy-conscious landscape.

Key Performance Improvements Achieved with VFD Implementation

The implementation of Variable Frequency Drives (VFDs) for AC motors brings about significant performance improvements that enhance overall operational efficiency. One of the primary advantages of VFDs is their ability to precisely control motor speed and torque based on the actual demands of the application. This dynamic adjustment minimizes energy waste, allowing systems to operate at optimal levels without unnecessary energy consumption. As a result, key performance indicators such as throughput and production quality can see marked enhancements.

Moreover, VFDs contribute to reducing mechanical stress on equipment, which leads to lower wear and tear over time. This reduction in strain results in longer service life for motors, which reduces maintenance costs and downtime. Additionally, by enabling soft starts, VFDs allow motors to ramp up to speed gradually, reducing inrush currents and associated electrical stresses. This not only increases the longevity of the motor but also ensures that other connected equipment operates more reliably, ultimately yielding more consistent performance across the entire system.

The overall result is a more efficient, reliable, and productive operation that meets modern energy standards and performance expectations.

Cost Savings and Return on Investment from Using VFDs

Variable Frequency Drives (VFDs) have emerged as a pivotal solution for enhancing energy efficiency in AC motors. One of the primary advantages of using VFDs is the significant cost savings they offer. According to the U.S. Department of Energy, optimizing motor operation through VFDs can reduce energy consumption by as much as 50% in certain applications. This reduction in energy use directly translates into lower utility bills, allowing businesses to allocate resources more efficiently and invest in further improvements.

Moreover, the return on investment (ROI) from implementing VFDs can be remarkably quick. Studies indicate that companies can recoup their initial investment in VFD technology within 2 to 3 years, depending on the operational context and energy costs. Industries that rely heavily on motor-driven processes, such as water treatment, HVAC, and manufacturing, can particularly benefit from the enhanced control that VFDs provide. This control not only matches the motor output to the load requirements but also minimizes wear and tear on equipment, thereby extending its lifespan and reducing maintenance costs. The dual benefits of savings and reduced operational costs position VFDs as a strategic investment for entities looking to improve their bottom line while pursuing sustainable energy practices.

Environmental Benefits of Enhanced Energy Efficiency with VFDs

The implementation of AC motor VFDs (Variable Frequency Drives) significantly enhances energy efficiency, leading to substantial environmental benefits. By allowing for precise control over motor speed and torque, VFDs enable equipment to operate only at required levels, reducing energy consumption. This decrease in energy usage translates directly into lower greenhouse gas emissions, as less energy generation often means reduced fossil fuel reliance. Furthermore, a more efficient energy use minimizes the demand on power plants, thus helping to decrease air pollution and its associated health risks.

Moreover, VFDs facilitate smoother operation and reduce wear and tear on equipment, which can extend their lifespan. As motors perform optimally with VFD technology, there is less energy wasted on excess heat and friction. This not only conserves resources but also reduces the frequency of repairs and replacements, further decreasing waste. The collective impact of these efficiencies and the extended operational lifespan contributes to a more sustainable industrial ecosystem, aligning with global initiatives aimed at reducing environmental footprints and promoting energy conservation strategies.

Related Posts

-

10 Best VFD Controllers You Need to Know for Optimal Performance

-

Exploring Innovative Alternatives to Frequency Drive Controllers for Enhanced Performance

-

Exploring Motor Frequency Converter Alternatives for Enhanced Energy Efficiency and Performance

-

Unlocking Energy Efficiency: How Motor Frequency Converters Transform Industrial Operations

-

Understanding the Benefits of Variable Speed Drives in Modern Industry

-

7 Reasons Why the Best 220v VFD Single Phase is a Game Changer for Your Business